MARTINCSI

Electrical toolset helps make ice cream sandwich machine a reality

AUTOCAD CUSTOMER SUCCESS STORY

Share this story

MartinCSI delivers solutions for industrial manufacturing

As a systems integration company solving industrial manufacturing and process challenges, MartinCSI takes on a wide variety of projects. Ranging from programming PLCs to upgrading controls and integrating motion drives and vision systems, the company’s team of engineers create innovative solutions no matter the customer or industry. And they rely on AutoCAD and the Electrical toolset to make it happen—including using it for an ice cream sandwich filler machine.

Electrical toolset cools the design work for ice cream sandwich filler machine

Based in the Columbus, Ohio area, MartinCSI helps manufacturers integrate their electrical controls and solve industrial manufacturing challenges, including programming programmable logic controllers (PLCs), upgrading controls, integrating motion drives and systems, and more. No project is too big or too small. And the type of industry isn’t a factor either.

Over the years, MartinCSI has helped to provide solutions for one particular customer—a manufacturer of novelty ice cream filling machines. The most recent challenge was developing the electrical panel for a new filling machine that produces ice cream sandwiches. However, voltage was an issue.

Text + Image (Right)

“We needed to separate the control panel so the high voltage was separated from 24 volts,” says Carlos Rodriguez, engineer, MartinCSI. “Generally, these machines are pretty small, and it's not really feasible to have high voltage open while they're in production. Having twenty-four volts separated was an important part of that.”

The actual design of the filling machine was designed by the customer and Rodriguez focused on developing the electrical system for it.

Ice cream sandwich filler machine. Courtesy of MartinCSI.

Text-only; 1 column

“AutoCAD and the Electrical toolset were used to design all the schematics and all our panel layouts for them to be able to build their machine,” Rodriguez explains. “For the filling machine, we actually have several servo motors so our design is managing and showing power. AutoCAD and the Electrical toolset really came into play because we had such small panels and needed to fit a lot of different components into a panel. By using the Electrical toolset, we could ensure that we have all of the right spacing and distance so it doesn’t overheat.”

One-of-a-kind capabilities with the Electrical toolset

Of course, it’s more than just ice cream manufacturing machines for MartinCSI. With the company’s variety of customers across industries, the electrical engineering team relies on AutoCAD and the Electrical toolset to solve numerous challenges.

“With a combination of our own templates and the electrical diagrams and panel layouts provided in AutoCAD and the Electrical toolset, we can create our designs for many different customers,” says Bryan McDonald, engineer, MartinCSI. “We have a number of standards, and our IT department has also created and/or obtained blocks of equipment from manufacturers. That way we can just type in the manufacturer part, grab it, place it in the drawing, and it’s right there.”

Having worked on projects that used AutoCAD and the Electrical toolset and others that didn’t, McDonald has learned the difference from experience especially when it comes to details and alignment.

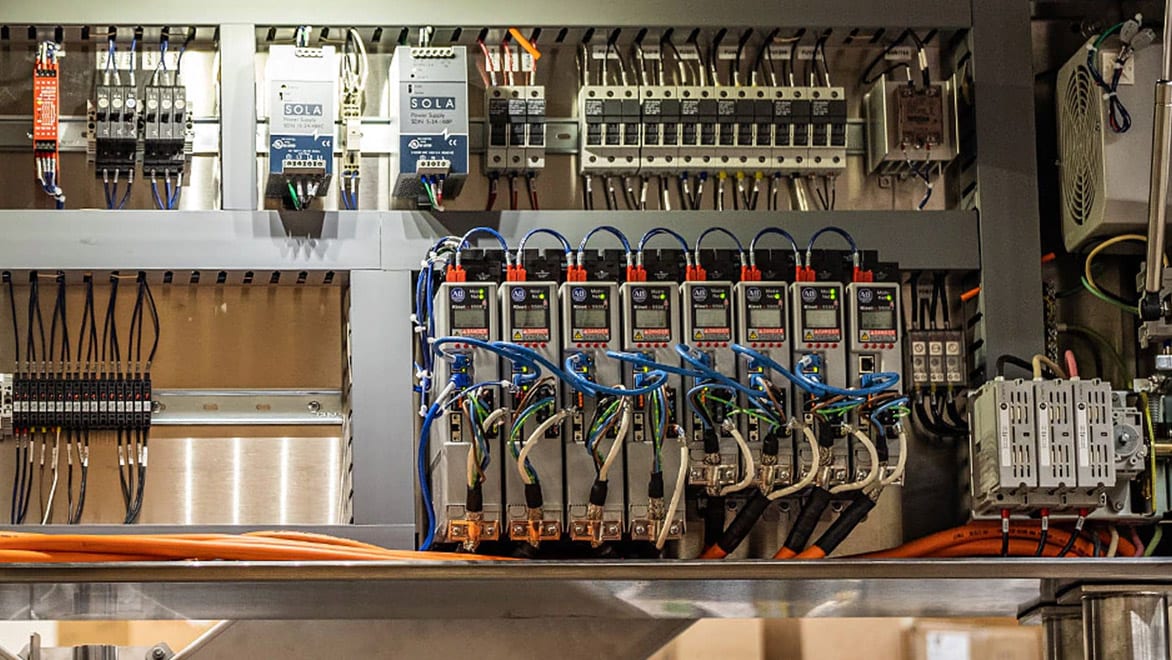

Full control panel for ice cream sandwich filler machine. Courtesy of MartinCSI.

Text + Image (Right)

“You really learn to appreciate the additional features of the Electrical toolset, including things like automatic wire numbers, project-wide component tag and cross-reference updates; the PLC database file editor; one-click ladder and rung inserts; and source and destination arrows,” McDonald says. “Making basic changes takes a lot longer without the toolset. Even coming down to little things like being able to align components so everything is straight in a row.

“If you work on a design that didn’t use AutoCAD, you have to physically drag each component,” he continues. “Whereas in AutoCAD you just click on one with AEAlign (Align under the Edit Components tab), select all of them, click again, and, boom, they’re all in a straight line. I'm pretty picky when it comes to my drawings and being sure things are aligned and look nice. For me, it's a big help having those features that AutoCAD and the Electrical toolset bring.”

For Rodriguez, wire numbers in the Electrical toolset are the game-changer when working on their projects.

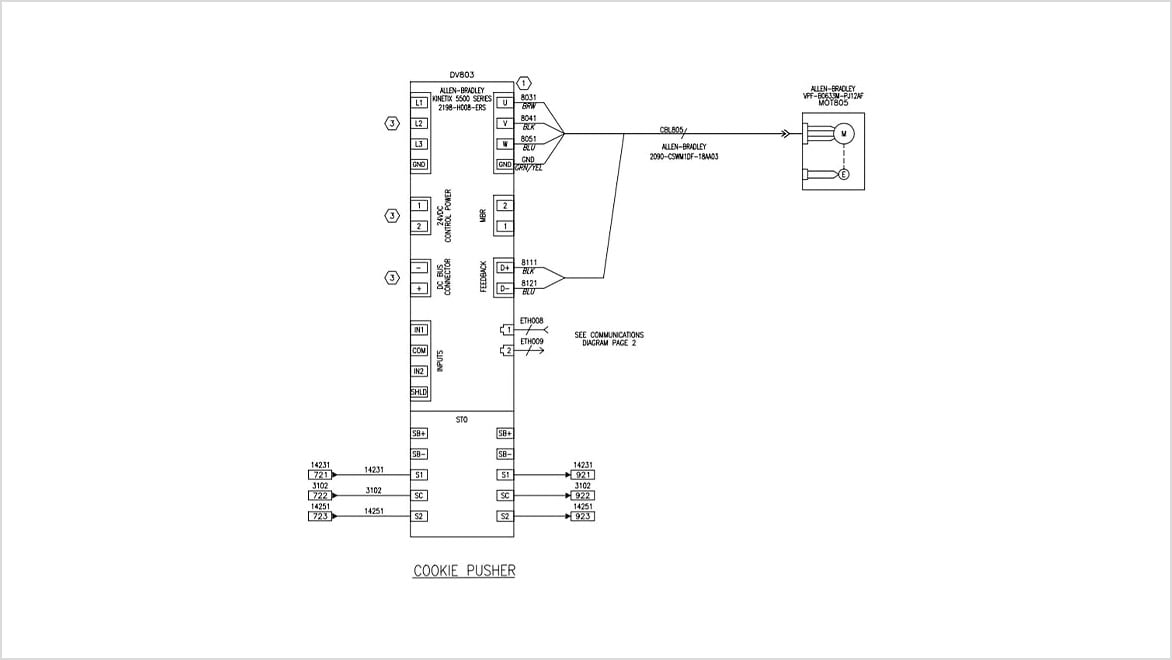

Drawing for portion of electrical control panel. Courtesy of MartinCSI.

Text-only; 1 column

“From my perspective and in schematics, the Electrical toolset is a must just because of wire numbers,” he says. “Every wire that we lay out must have an identified tag so that we can identify what it is later down the road. A lot of other companies do this manually—label each wire and then make sure the schematics are drawn up and there are the right numbers for everything. One of the most important things in AutoCAD and with the Electrical toolset is the ability to tag all of the components’ wires and make sure they are labeled correctly when we go out in the field. It dramatically increases our efficiency and accuracy.”