CUSTOMER STORIES

Smart manufacturing with digital tools

FUTURE OF MAKING THINGS

Share this story

A comprehensive platform to adapt to the requirements of Industry 4.0.

Pinto Brasil, a company specialising in metal work, have developed their digital product data management platform by taking advantage of solutions from Autodesk, which include Autodesk Inventor, AutoCAD Electrical and Autodesk Vault Professional. Benefits to date have included greater control of their production system activities, a reduction in engineering execution times and improved automation of the factory floor's management processes.

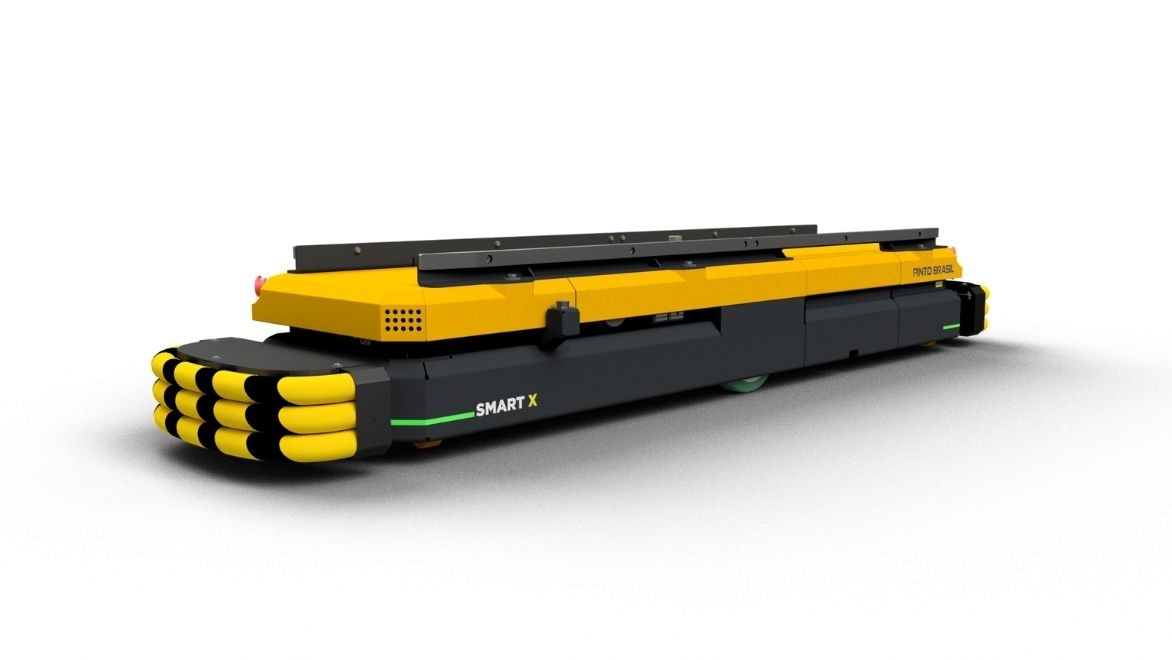

Application Center. Coutesy of Pinto Brasil.

Committed to research

Since 1991, Pinto Brasil has specialised in metal work primarily in the automotive industry and are a main supplier to some of the largest companies in this industry. As such, they are committed to complying with the sector's most rigorous standards and are currently involved in the design, development, and production of industrial solutions for assembly lines and intralogistics.

The commitment to research and development is one of the company's sustainability pillars with a focus on creating cooperative R&D relationships together with scientific bodies, customers, suppliers and other third parties. This is helping ensure that long-term sustainability is core to their solutions reliability and integrity.

Digitalization. Courtesy of Pinto Brasil.

The key to digital integration

Since 1991, Pinto Brasil has specialised in metal work primarily in the automotive industry and are a main supplier to some of the largest companies in this industry. As such, they are committed to complying with the sector's most rigorous standards and are currently involved in the design, development, and production of industrial solutions for assembly lines and intralogistics.

The commitment to research and development is one of the company's sustainability pillars with a focus on creating cooperative R&D relationships together with scientific bodies, customers, suppliers and other third parties. This is helping ensure that long-term sustainability is core to their solutions reliability and integrity.

“As Pinto Brasil is a company in the technology industry that is focusing on the Design, Development and Production of Assembly Lines and Intralogistics Systems in Industry 4.0, where the management of product information and level of functional customization of equipment is growing, it has become imperative that the company's digital transformation program is integrated, circular and sustainable.”

—António Brasil, CEO, Pinto Brasil

Inside of the Application Center. Courtesy of Pinto Brasil.

Automated records management

The solution, consisted of adding AutoCAD Electrical and Autodesk Vault Professional into the overall digitization project, in addition to their existing Autodesk portfolio.

These two new additions now enable all project data within Autodesk Inventor and AutoCAD Electrical to be assigned within the Vault, whilst conformity of the information and management of versions is ensured through its data lifecycles. The development of an internal platform for creating entities, has embedded validation workflows and integration with various business systems, from the company's Management ERP, PRODUSI® the Business Processes Management software and GenSYS® the Shopfloor Management and Control software.

Communicating structured BOMs of Pinto Brasil's products and the automatic generation of routings between Vault and GenSYS®, ensures all information needed for medium-term planning (for example MRP and CRP), as well as job allocation and process sequencing for the Shopfloor is available and up to date.

“Nowadays, it is absolutely essential that we link all of the product design to the company's other operations. All the detail that the Autodesk tools allow to be managed, from BOMs to work instructions, is pivotal in the interaction and optimization of processes in the other procurement/supply, logistics, production departments, etc.”

—Micael Gonçalves, Digital Transformation Leader, Pinto Brasil

Digitalization. Courtesy of Pinto Brasil.

More activity in less time

Once the product engineering objective is successfully complete, the digitization process at Pinto Brasil triggers the automatic creation of all the necessary data in the ERP system and on the Shopfloor Management platform GenSYS®.

With the mechanical design being carried out in Inventor, together with the electrical project being developed in AutoCAD Electrical, all connected with Vault Professional, through a layer of integration with other software, ensures, in addition to the intangible benefits, a higher degree of product conformity and version management, an increase in standardization activities and use of common parts, a general reduction in the lead time of engineering activities (product and process) and the automation of Shopfloor Management processes.

In its day-to-day operations, Pinto Brasil uses Autodesk’s Collection tools to support its engineering decisions, since the modular nature and configuration of its solutions enable a faster response that is more interactive with its customers. These tools include Autodesk Vault Professional and the Autodesk Product Design and Manufacturing Collection which includes Autodesk Inventor, AutoCAD Mechanical, AutoCAD Electrical, Autodesk Navisworks and Autodesk Inventor Nastran.

“The Autodesk product design tools have, for a long time, been absolutely fundamental in the day-to-day operations of Pinto Brasil's engineering teams. The recent incorporation of Vault Professional in our information management system has extended this partnership to all the operating teams, as it is a point of integration with all the other management tools.”

—César da Silva, Engineering Manager, Pinto Brasil

Digitalization. Courtesy of Pinto Brasil.

An essential partnership

It was Asidek, Autodesk Platinum Partner and main Iberian integrator of Autodesk solutions, with over 25 years of experience, who supported Pinto Brasil during their digitization process implementation and therefore played a key role in this project. The collaboration during several product demonstration sessions established how they could support and develop the desired solution. In the pre-implementation phase of the project, several training and consultation engagements were delivered by Asidek, with a view to equipping Pinto Brasil's engineering teams with the necessary knowledge for better utilisation of their tools, in particular Vault Professional.

Also, Asidek played a key role in supporting several process development actions, with the ultimate aim to ensure continuous improvement and productivity gains, by making the most of their Autodesk tools