Elevate your design and manufacturing processes with Autodesk Fusion

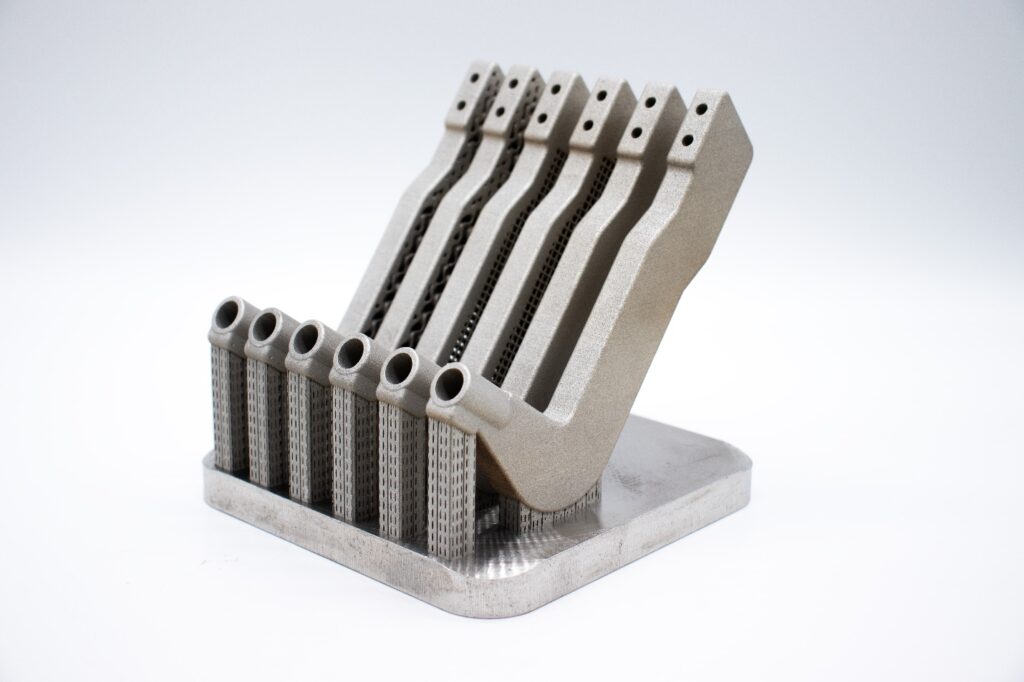

Autodesk Fusion supports several 3D printing technologies. One of them is Metal Powderbed Fusion (MPBF), which encapsulates all metal powderbed technologies (SLM, DMLS, and EBM). This additive technology has been in Fusion for some time, but with the introduction of advanced functionality including process simulation, it’s starting to gain traction in the industry.

You can access Metal Powderbed Fusion (MPBF) workflows via the Autodesk Fusion Manufacturing Extension, which enables the creation of toolpaths and support strategies for MPBF additive technologies. It gives you the ability to produce metal parts using powder bed fusion machines. Additionally, you can access advanced control to automatically orient parts, generate fully associative support structures, and pack parts to optimize the use of the build space.

What’s the MPBF workflow like in Fusion?

Just like most workflows in Autodesk Fusion, the MPBF workflow in Fusion is intuitive and powerful. It follows a similar structure as other industry 3D printing tools but keeps the user experience consistent with other workspaces in Fusion.

To begin the MPBF workflow, start by creating a setup. To do this, you must decide what machine and which set of build parameters (print settings in Fusion) you want to use. From the setup, you can modify print settings and, if needed, you can assign different print settings to different models on the build platform.

Check out the below tutorial to learn more:

Orientation and generating support

Having selected the machine and print settings, you now need to orient the parts and place them correctly on the build platform. You can do this manually or automatically depending on your preference.

Once positioned, support structures are added to the components. In Fusion, because we deal with solid CAD geometry, we can select specific CAD features to apply supports. It’s also possible to do the same with mesh bodies in Fusion.

Check out the below tutorial to learn more:

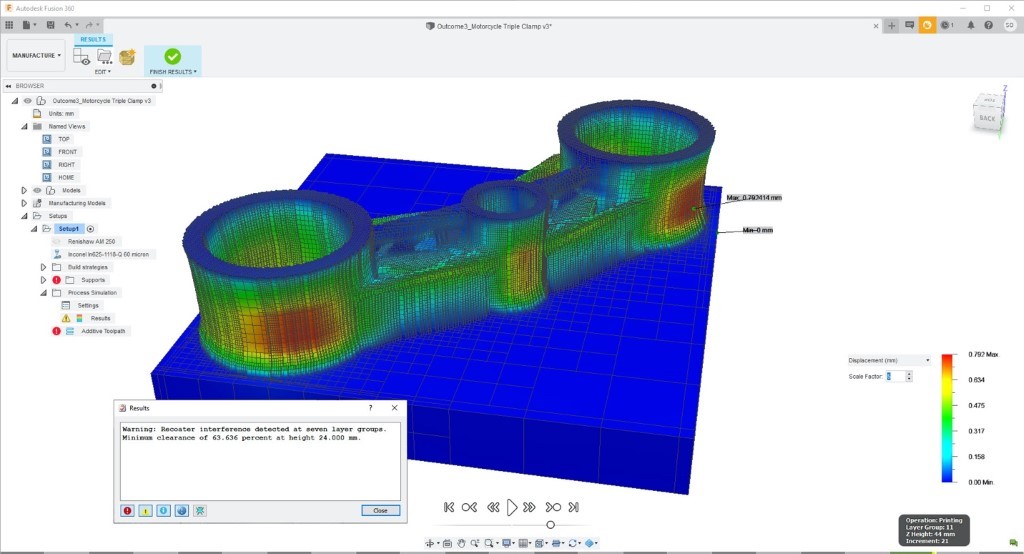

Simulating the toolpath and creating the build file

Finally, you can simulate the toolpath. Once you’re happy with the simulation results, you can create a build file and load it onto your machine. For those who want to simulate the MPBF process in software before they run their build, you can also run a process simulation.

Check out the below tutorial to learn more:

We hope this article gives you a more thorough understanding of how to leverage metal 3D printing tools in Autodesk Fusion. Ready to give what you learned a try?