Elevate your design and manufacturing processes with Autodesk Fusion

Learn the basic concepts of sheet metal fabrication, including an overview of measurement units, manipulation techniques, and metal types.

What is Sheet Metal?

Sheet metal is a widely used material across several different industries. It can be crafted from an assortment of metals like steel, aluminum, copper, brass and is versatile enough to be used in various applications, including industrial and manufacturing. Sheet metal can be precisely manipulated because of its flexibility, durability, and tensile strength, offering many benefits to the modern designer.

Measurement Units

Sheet metal thickness determines the correlating terminology — plates, sheets, or foils. Foil thickness is usually defined up to 0.2 mm, with sheet metal ranging from 0.5 mm to 6 mm. Anything above 6mm is defined as a metal plate.

Three different units measure thickness: gauges, millimeters, and mils. Gauge is the metal’s thickness in relation to its weight per square foot, with a higher gauge indicating a thinner sheet of metal.

Sheet Metal Fabrication

Sheet metal fabrication uses sheet metal to build machines, structures, panels, brackets, and more. There isn’t a singular way to form or use sheet metal, which is why it is widely used across various applications. Forming processes include a long list of techniques, including:

Stamping

Metal stamping is a cold-forming process. Dies and stamping presses are utilized to manipulate sheet metal into different shapes for many applications. Stamping is quick and affordable, which is ideal for producing large quantities of perfected components. Some of the machining techniques within the stamping process are embossing, bending, and coining.

Bending

As the name implies, bending is the process of shaping metal into desired shapes. Metal is typically bent around a single axis. The goal is to bend the metal above the yield point but below the tensile strength.

Roll Forming

Roll forming is the process of feeding metal through rollers to create a uniform bend down the entire length of the metal sheet resulting in a coil.

Stretching

Stretching a thin sheet of metal is about as simple as it sounds. Metal materials are stretched or pulled apart using various hand tools or machines.

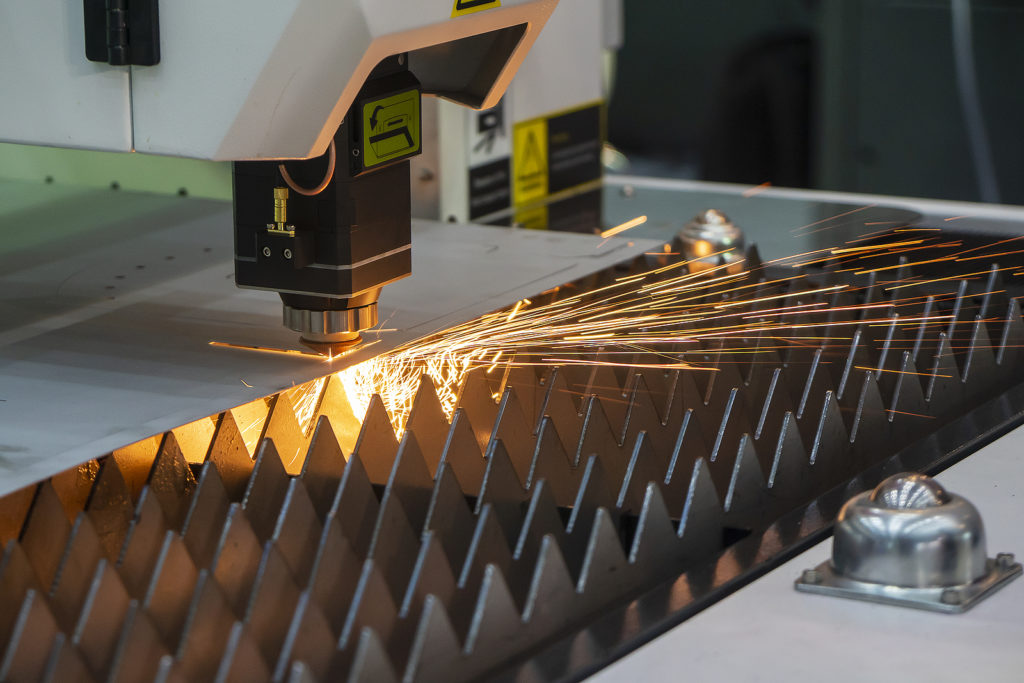

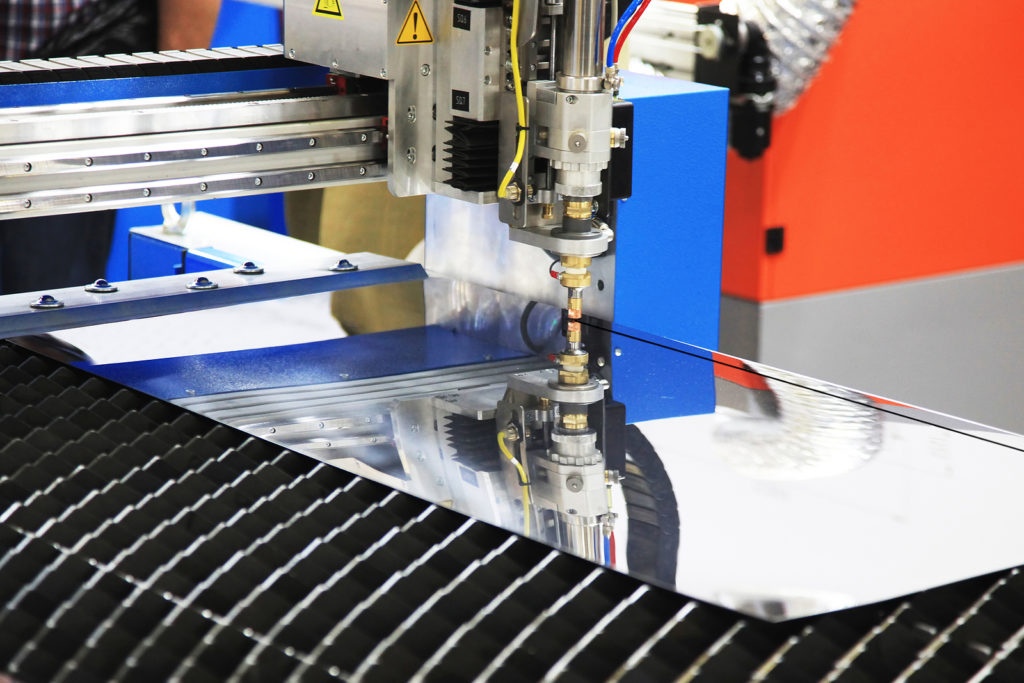

Cutting with CNC Machines

Sheet metal cutting in industrial/manufacturing applications is a precise process that uses computer numerical control (CNC) machines like lasers, plasma, waterjet, etc. CNC machines are used to produce precisely engineered parts. Autodesk’s Pier 9 workshop has an impressive sample of CNC machines. When it comes to working with metal, automated systems are a human’s best friend.

Types of Sheet Metal

Depending on the desired application and manufacturing process, sheet metal can consist of several different metal types. Aluminum and steel are the most versatile metals and are used across various applications.

Aluminum

Although it might not be as strong as steel, aluminum is an excellent lightweight alternative. It works well in low temperatures, so it is often used in cold climate applications like refrigeration, aerospace engineering, roofing, etc.

Steel

Steel is strong and versatile, and it comes in a few different subgenres: stainless steel, galvanized steel, carbon steel, and black iron steel.

Copper

Copper is often used for decorative applications but is also a great conductor and corrosion-resistant.

Magnesium

Magnesium is a stiff and sturdy metal with a low density. Recently, a new magnesium alloy was produced for the automotive industry that could replace aluminum in the body panels of some automobiles.

Brass

Brass is an excellent metal for fittings and components. The acoustic properties and corrosion resistance of brass make it ideal for instruments and firefighting equipment like nozzles, fittings, and wrenches.

Bronze

With a low melting point and superior strength to copper, bronze is used to make coins, decorative architecture, and wires.

Fusion 360 Sheet Metal Workspace

Ready to design sheet metal parts? Autodesk’s Fusion 360 is an integrated CAD/CAM tool that features a sheet metal workspace that enables you to design your project with manufacturing in mind. Features like the One Flange Tool, which combines five flanging commands (base, edge, contour, miter, and swept) into one command, make it a user-friendly tool for designers at all levels.

Fusion 360 Sheet Metal Tutorials

To get started, check out these Fusion 360 tutorials for instructions and real-world examples to inspire your next project:

- Sheet Metal Contour Flanges

- Sheet Metal Parametric Flange

- Sheet Metal Gems Part 1

- Sheet Metal Gems Part 2

Try Fusion 360 today to access innovative and consolidated tools to contour and shape your next sheet metal project.