& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

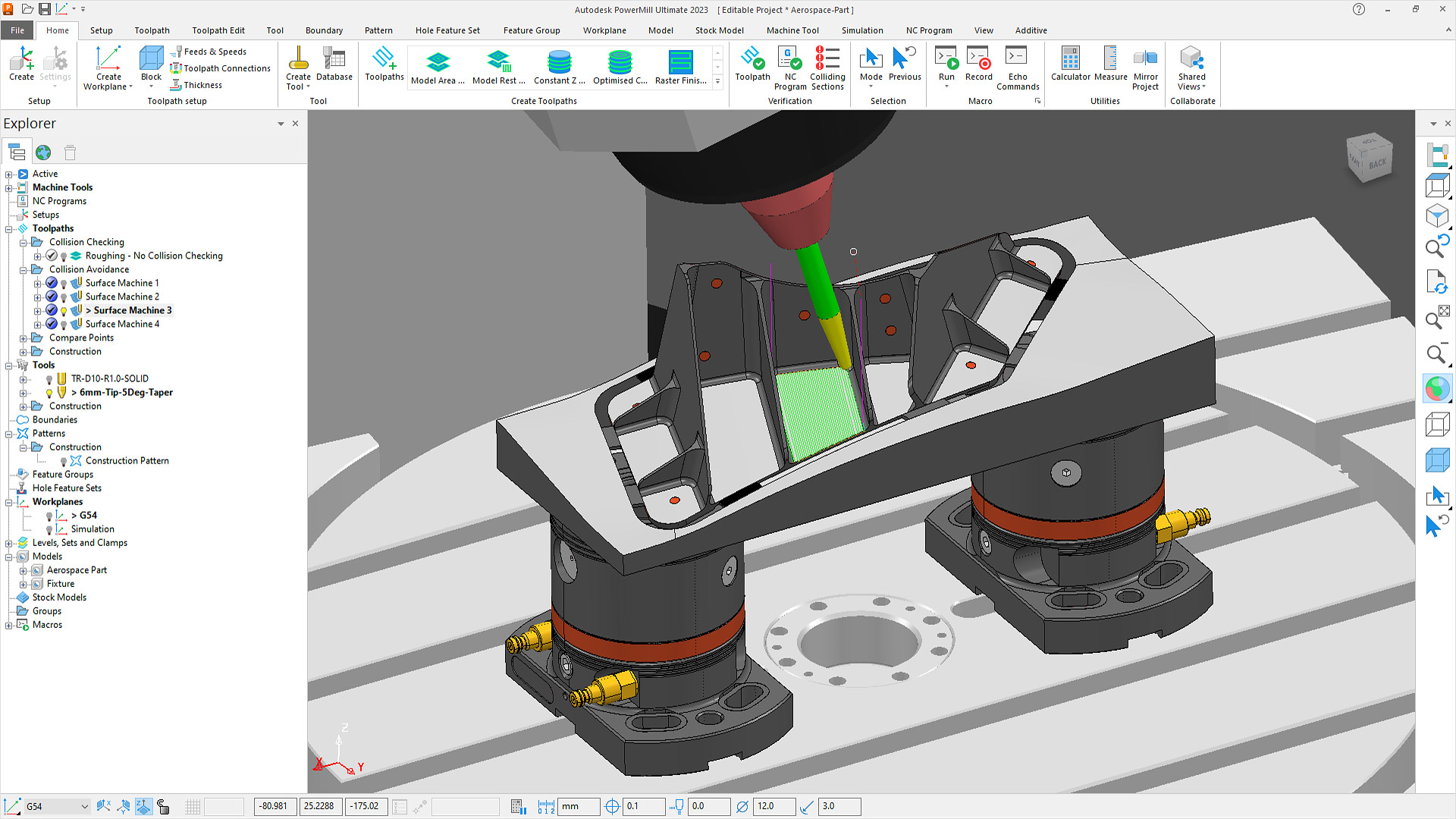

The evolving capabilities in Fusion with PowerMill® enable easier 3- and 5-axis CAM programming, helping manufacturers get more from their subtractive, additive, and hybrid machines.

Import surfaces, solids, or meshes from mainstream CAD systems and produce NC code even if data is poor quality

Choose from a range of roughing strategies to remove material quickly and maximize cutter life

Access a library of finishing toolpaths to produce precision parts with exceptional surface finish

Simplify 3+2 and 5-axis machining to produce parts with fewer setups, shorter tools, and faster feeds and speeds

Make global or localized edits to your toolpaths without the need for lengthy, wasteful recalculations

Check individual toolpaths or entire projects to find and fix problems before they cause expensive mistakes

Use a 3D model of your CNC machine to simulate toolpaths and identify collisions, near-misses, or over-travel

Use configurable post-processor files to export safe and efficient NC code to suit your specific machine

Embed your best practices into templates and macros and share with others to automate common tasks

Create, control, and simulate deposition strategies for driving high-rate additive processes such as DED and FFF

Offline programming and simulation of industrial robots with analysis to avoid singularities and over-travel

Access specialized strategies to manufacture ports, manifolds, blades, blisks, and impellers

Expert performance

PowerMill uses 64-bit, multi-threading technology to complete common CAM programming tasks faster, even on large, complex parts consisting of surfaces, solids, or meshes. Faster processing times mean you can start machining sooner or explore alternative solutions. (video: 2:46 min.)

High-efficiency roughing

Choose from a range of roughing strategies to remove material quickly and efficiently. Advanced options allow you to configure the toolpath to suit your specific tool type and material, helping maintain constant tool load and maximize cutter life. (video: 3:14 min.)

Comprehensive finishing

Access a vast library of finishing and rest-finishing toolpaths for increased programming flexibility. Achieve exceptional levels of precision and surface finish using advanced settings that suit your specific CNC machine, resulting in parts that require little to no manual polishing. (video: 3:01 min.)

Rest finishing

Choose from a range of toolpaths designed to accurately identify and efficiently remove unmachined stock from previous operations or cutting tools. (video: 2 min.)

Toolpath optimization

Use powerful toolpath editing options to make global or localized changes to toolpaths without the need for lengthy recalculations. Choose to delete, limit, reverse, reorder, combine, or divide entire toolpaths or individual segments using different selection methods. (video: 2:42 min.)

Machining setups

Use separate machining setups to help manage how you cut parts, resulting in faster CAM programming and fewer mistakes. Set default values for setup parameters such as model location, collision checking against fixturing, output workplane, CNC machine, and more. (video: 1:52 min.)

Cutting tool support

Build a searchable database of cutting tools and share with your team for greater consistency. Define tool and holder geometry, including standard cutters and customized form tools. Automatically calculate feeds and speeds based on stock material.

Efficient 3+2 machining

Use the rotary axes of your machine to access undercuts and other difficult-to-reach features in a single setup. Alternatively, use shorter, more rigid tool assemblies combined with more aggressive feeds and speeds to improve quality and reduce cycle times. (video: 2:08 min.)

Inclined flat finishing

FUSION WITH POWERMILL ULTIMATE

Experience a finishing strategy that automatically finds all flat regions within a CAD model, then machines them with a single, 5-axis toolpath. Use with flat bottomed cutting tools. (video: 1:40 min.)

5-axis simultaneous

FUSION WITH POWERMILL ULTIMATE

Machine the most challenging parts safely and efficiently with simultaneous 4- and 5-axis machining. Choose from a suite of dedicated multi-axis strategies and tool-axis controls to finely control the motion of your 4- and 5-axis CNC machinery. (video: 3:22 min.)

Expert 5-axis controls

FUSION WITH POWERMILL ULTIMATE

Make changes to the 5-axis motion of your toolpaths using a range of intelligent edits. Change the tool orientation in local regions or apply smooth interpolations between others to avoid erratic motion that could compromise surface finish. (video: 2:49 min.)

Automatic collision avoidance

FUSION WITH POWERMILL ULTIMATE

Automatically identify and avoid any collisions or near-misses involving the cutting tool and workpiece. Use the rotary axes of your machine to safely and smoothly tilt the tool away and avoid costly mistakes. (video: 56 sec.)

Dynamic machine control

FUSION WITH POWERMILL ULTIMATE

Use a 3D model of your 5-axis CNC machine tool to select the best tool-axis orientation to machine parts safely and efficiently. Dynamic drag handles and visual feedback help identify collisions and axis over-travel to speed up CAM programming. (video: 1:21 min.)

In-cycle probing

FUSION WITH POWERMILL ULTIMATE

Access dedicated probing routines to measure 3D surface geometry with spindle mounted touch probes. Use resulting measurements to simplify part setup and monitor the quality of machined parts throughout the machining process. Produce inspection reports and share via Autodesk Drive. (video: 2:06 min.)

Offline robot programming

FUSION WITH POWERMILL ULTIMATE

Use this dedicated interface to streamline the offline programming of industrial robots for additive and subtractive applications. Simulate and optimize your toolpaths using an accurate 3D model of your robot to reduce axis singularities and over-travel. (video: 2:55 min.)

Electrode manufacture

FUSION WITH POWERMILL ULTIMATE

Automate the design, manufacture, inspection, and electrical-discharge manufacturing burning of electrodes. Use customizable machining templates to automate the production of families of electrodes for increased process consistency, and to help avoid mistakes happening on the shop floor. (video: 2:46 min.)

Hybrid manufacturing

FUSION WITH POWERMILL ULTIMATE

Create, control, and simulate deposition strategies for driving high-rate additive processes, such as Directed Energy Deposition (DED) and Fused Filament Fabrication (FFF). Combine additive and subtractive toolpaths to enable hybrid manufacturing workflows using suitable CNC machinery. (video: 2:42 min.)

Blisks, blades, and impellers

FUSION WITH POWERMILL ULTIMATE

Simplify the CAM programming of blisks, integrally bladed rotorsblades, and impellers with dedicated 5-axis machining strategies. Roughing and finishing strategies use advanced tool-axis smoothing, resulting in safe and predictable machine motion and exceptional surface finish. (video: 1:37 min.)

Engine ports and manifolds

FUSION WITH POWERMILL ULTIMATE

Access specialized 3-axis and 5-axis machining strategies to automate the CAM programming of engine ports and manifolds. Use advanced toolpath controls to regulate surface finish and improve the flow of fluid/gas resulting in optimal part performance.

Rib machining

FUSION WITH POWERMILL ULTIMATE

Produce cutter-friendly toolpaths to mill the deep ribs and slots commonly found in molds and dies. Toolpath offsets are optimized to maintain a constant tool load, prolonging tool life and reducing the risk of tool failure. Use as a low-cost alternative to EDM.

Toolpath and machine simulation

Simulate your 3- and 5-axis toolpaths using a 3D digital twin of your CNC machine. Avoid costly downstream problems by visualizing machine motion in a virtual environment to fix problems, including machine over-travel, axis reversals, and more. (video: 1:46 min.)

Stock removal simulation

Simulate the removal of material from a virtual stock piece. Use advanced analysis tools to identify un-machined stock with different colors. Instantly highlight any gouges involving the cutting tool or collisions with the tool holder for increased peace of mind. (video: 1:16 min.)

Advanced analysis

FUSION WITH POWERMILL ULTIMATE

Access a range of advanced options to analyze toolpath behavior to predict the quality of your CNC machined parts. Instantly visualize defects that could be caused by undesirable rotary axis motion. Experiment with different feeds and speeds to simulate the impact on surface finish.

Automatic project verification

FUSION WITH POWERMILL ULTIMATE

Carry out detailed safety checks of entire projects, including toolpaths and NC programs. PowerMill uses background processing to check for gouges, collisions, and more, meaning you can continue part programming to save you time and increase confidence in the safety of your NC programs.

Verification exports

FUSION WITH POWERMILL ULTIMATE

Quickly transfer your NC programs, CAD model, stock definition, tooling, datums, and other important data to third-party verification software for more in-depth analysis and added peace of mind.

PowerMill Viewer

Included in a subscription to PowerMill, the Viewer improves cross-team collaboration by allowing extended team members to open PowerMill projects. Use the viewer to review toolpaths, confirm datum locations, check tool assemblies, check for machine collisions, and more. (video: 1:26 min.)

Every CAD support

Import common CAD file types from mainstream design systems, including surfaces, solids, or meshes. PowerMill excels at handling poor quality data, meaning you can instantly start creating high-quality toolpaths and NC code without wasting time fixing models.

Customization and automation

Embed your machining best practices into templates, macros, and toolbars that can automate common tasks. Share these with new workers to help them become more productive, and free up experienced workers to handle more valuable projects.

Trusted NC code output

Rapidly output high-quality NC code for your CNC machine and NC controller. PowerMill includes a large library of editable post-processors that you can configure to meet your needs. For more advanced customization, additional support can be provided through our network of global resellers.

Setup sheets

Automatically produce 2D setup sheets to help communicate critical information with machine operators and other project stakeholders. Share details about models, fixturing, tooling, datums, and toolpath feeds and speeds to avoid mistakes and allow critical decisions to be made quickly.

Autodesk Drive and shared views

Securely store key PowerMill data in the cloud and share with internal and external members of your team for improved project collaboration. Use password protection to manage access across your team and keep your data and intellectual property safe.