& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

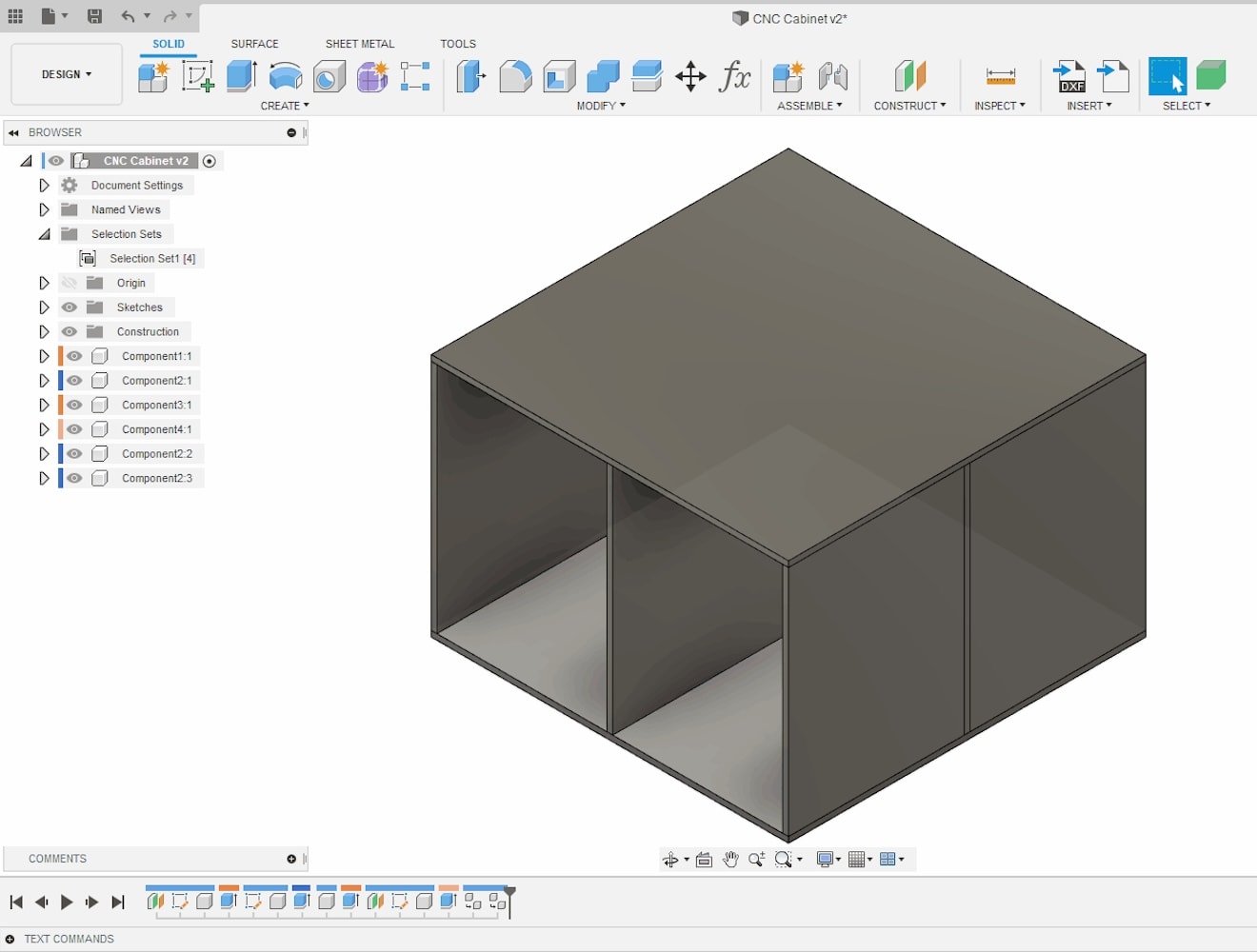

CNC cabinet software gives woodworking professionals the ability to create custom projects that meet the exacting standards of their clients. It greatly reduces the chance of costly mistakes while ensuring that the end products are of the highest quality.

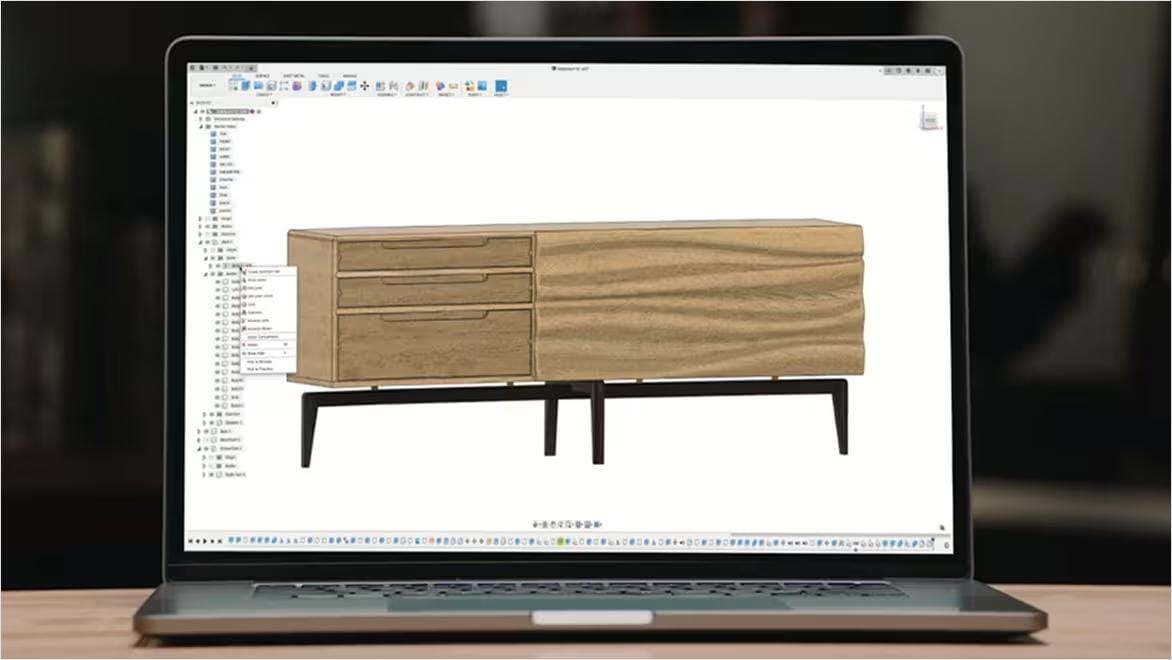

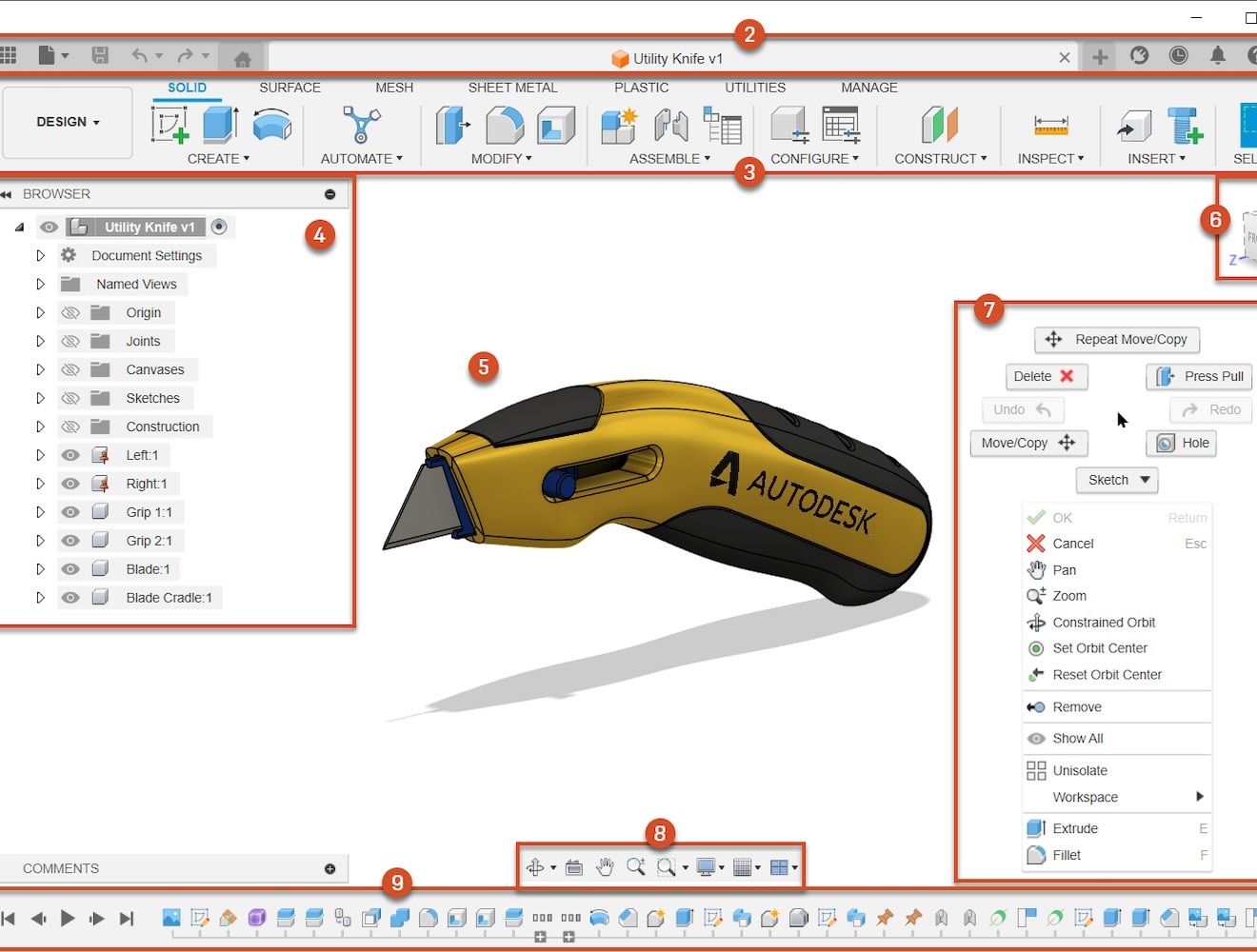

Autodesk Fusion combines CAD and CAM capabilities useful for designing and producing elegant cabinets. With its more streamlined CAM/CAM workflows, cabinetmaking professionals can quickly sketch designs and directly send them to a CNC machine.

By greatly reducing the need for manual measurements, Fusion also reduces human error, giving designers a powerful combination of meticulous planning and rock-solid execution.

Fusion combines robust design, engineering, and manufacturing tools into one versatile platform. Applicable for professional cabinetmakers or DIY enthusiasts remodeling a kitchen, Fusion is easy to learn and can help realize cabinets ranging from simple to complex designs.

More than ever, cabinetmakers can take advantage of CNC cabinet design software to iterate on designs until they land on the perfect version. Autodesk Fusion’s advanced 3D design and modeling capabilities have been tailored for more precise cabinet design, giving makers the ability to experiment and tweak concepts until they get the exact model they need.

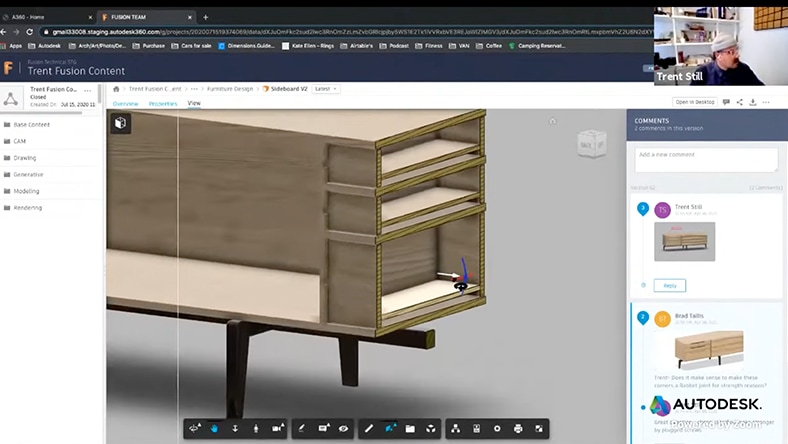

Autodesk Fusion offers real-time collaboration features so designers and other stakeholders can weigh in as a project evolves. With better teamwork, projects move faster and experience fewer roadblocks—key elements in keeping clients happy and the bottom line healthy.

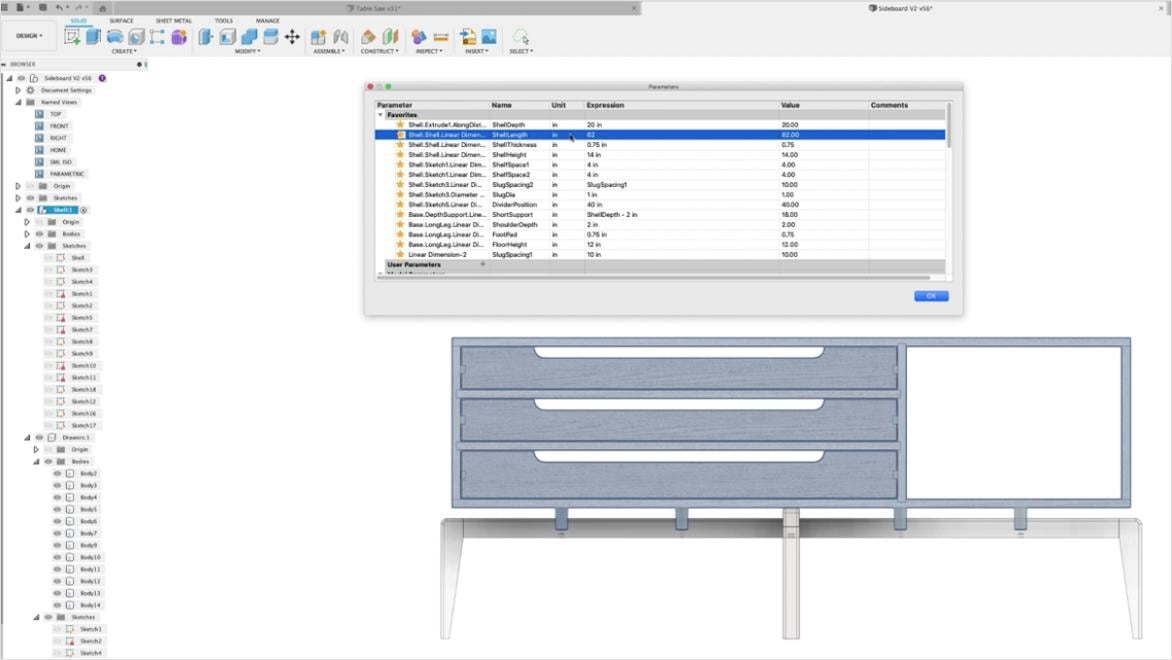

Some of Autodesk Fusion’s key features include design sketching, creating parametric features, and assembling components. These are crucial time-saving elements—for example, Fusion’s ability to create parametric features means cabinetmakers can make a change to a particular part of the design automatically without manually changing the dimensions over multiple sketches.

Finally, Fusion’s flexible design process boasts more precise constraints, so as you adjust a model, it will react as expected. Every detail will be more accurate, so when it’s time to fire up the CNC routers, cabinet makers won’t waste precious time and materials.

Fusion has all the functionality any cabinetmaker could want, but it’s especially flexible for professionals.

Advanced documentation features help cabinetmakers test geometric dimensions and tolerances, track changes made during design changes, and use exploded views to get a big-picture view of how a cabinet’s components will fit together.

Fusion’s extensive libraries and customization options can help cabinetmaking businesses scale wisely and manage highly complex projects.

One crucial aspect cabinetmakers must consider is software integration. Fusion is designed to work with third-party applications, so your shop will be able to use it without changing out the tools and systems you know well.

When building custom cabinets, precision is essential. Whether errors are introduced during the design process or when firing up a CNC machine, the result is the same: wasted time and resources. With Fusion, cabinet makers can fine-tune their designs to the smallest detail, so when production begins, every component will be correctly rendered.

Before any components are created, cabinetmakers need design software with extensive customization options. No client wants to hear that their choices have been constrained by software; Fusion’s flexibility means that cabinet makers can realize their clients’ most challenging design ideas.

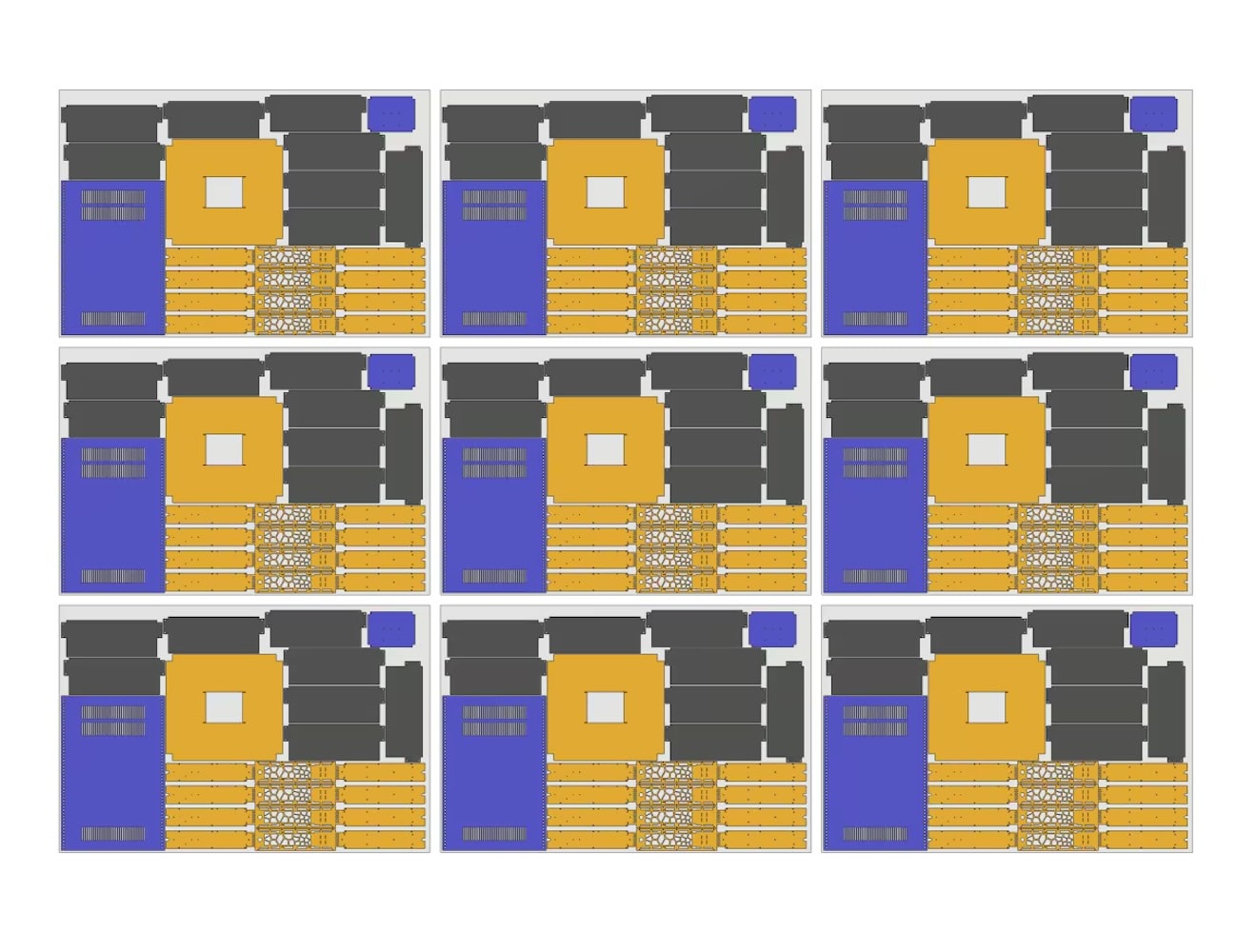

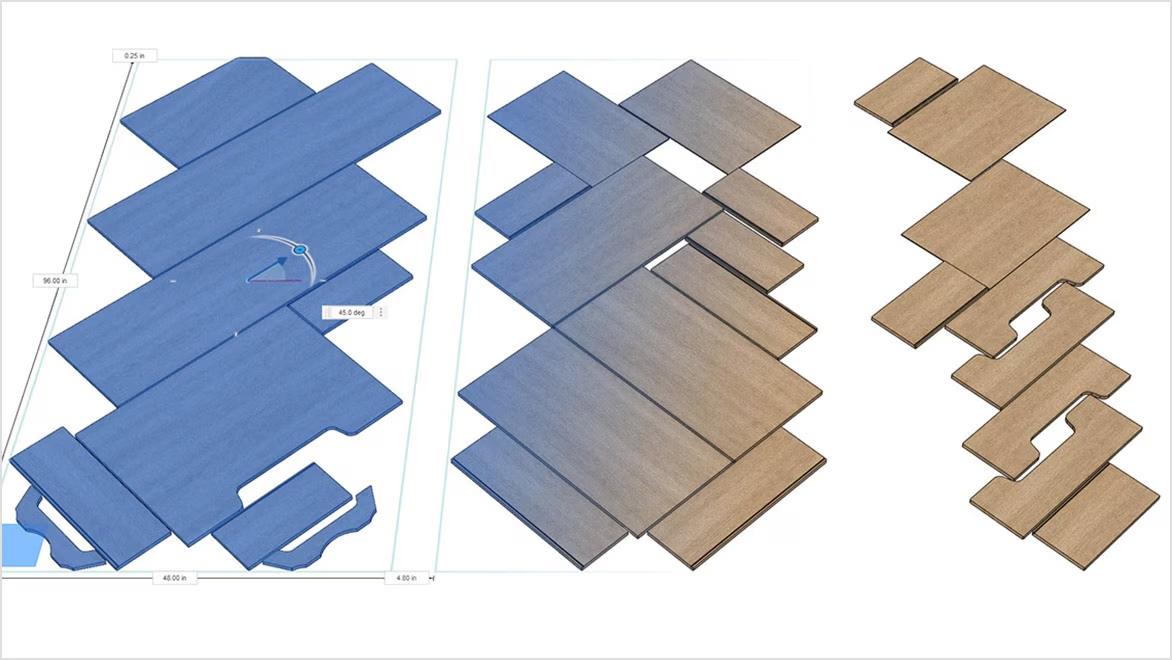

As a design comes together, an essential step is developing a cut list, where every component’s dimensions are meticulously detailed to ensure that premium wood isn’t wasted. To improve workflow efficiency, Fusion features cut list generation, as well as toolpath tiling and nesting.

Woodworking hobbyists and DIY makers can design and build their dream projects using Fusion’s free version, allowing them to earmark precious funds for materials and tools.

Fusion’s cost-effective pricing structure comes with robust customer support, as well as significant educational resources—benefits that free users can take advantage of as well.

Designing custom home cabinets might seem daunting for DIY enthusiasts, but Fusion offers advanced design tools that won’t strain the budget.

Fusion offers a user interface designed to get new users of every skill level up and running quickly.

Fusion’s product documentation, support forums, and online tutorials provide comprehensive support for DIY users.

For woodworkers focused on personal projects or who generate less than $1,000 in annual revenue, Fusion comes at an unbeatable price: free.

With Fusion, home cabinetmakers have professional-grade tools to create the high-quality woodworking projects they’ve been dreaming of.

Your time and resources are valuable. Fusion helps maximize efficiency by enabling superior precision in measurements and cuts, greatly reducing human error. Its automation features make job scheduling considerably easier, minimizing downtime. Fusion’s integration of design, validation, and manufacturing into one platform boosts overall production quality and efficiency.

Wasted wood equals lost revenue. Fusion offers efficient parts nesting and panel optimization, reducing waste. Highly accurate parametric controls in the design process also enhance production efficiency. The result? More cost-effective projects and better sustainability.

Fusion’s precise toolpaths yield high-quality cuts for consistency and peace of mind across projects. CNC cuts will be much more precise via detailed file formats, and simulation tools enable virtual testing of designs before production. More precise, accurate cuts reduce errors and the need for rework.

Manual work increases human error; Fusion’s automation features helps to streamline workflows from the design phase to the CNC machine stage. As a result, projects move faster and more smoothly, freeing cabinetmakers to focus on design.

One of Fusion’s key strengths is its efficient nesting of parts, which optimizes material usage. The software also provides essential guidance for how to set up a workspace properly and offers insights about basic design workflows. Once your design is ready, it’s easy to export your concept to your CNC machine.

The last thing a cabinetmaker needs is a struggle with setting up a workspace. Fusion’s intuitive and user-friendly interface simplifies the design process, and users can access helpful tutorials and lean on expert advice in community forums. Fusion’s effective tool configuration translates into a rich user experience marked by efficiency and design flexibility.

Fusion’s powerful design workflow capabilities make it easier to realize cutting-edge concepts. Its advanced 3D modeling helps you create, modify, and visualize your designs, and you’ll be able to test your concepts before making the first cut. That reduces unwelcome surprises during the production process.

For custom cabinetmakers, Fusion provides the seamless export of designs to G-code or DXF files for CNC machines. Once those machines are up and running, they’ll produce accurate, precise cuts. No matter what type of CNC machine a cabinetmaker uses, Fusion can export to it without a hitch. For professional cabinetmakers, that level of flexibility can make all the difference.

Nesting software analyzes the 2D shapes that need to be cut from a flat sheet of material and uses AI to arrange those shapes for maximum efficiency and minimal waste.

Fusion will be your strongest choice for CNC software. Cost-effective, more precise, and easy to learn, Fusion helps professional and hobbyist cabinet makers design and build quality products.

CNC software is preferred for cabinetmaking due to its precision, efficiency, and integration with CNC machines. It automates production, optimizes material use, handles complex designs, speeds up processes, and ensures consistency. Advanced features like toolpath generation and simulation enhance planning, making it ideal for manufacturing.

Yes. DIY cabinetmakers and home renovators can use Fusion for free for home-based, non-commercial products, as long as their work does not exceed $1,000 in revenue annually.

You can export G-code or NC code from Fusion to a CNC machine via a few easy steps. First, create a toolpath, then select the operations or setups that need NC code. Open the post processor dialog box, then choose the correct syntax for your CNC machine (you might need to change the file extension depending on your unit). Finally, click the Post button to create an NC code file your machine can read.

Yes! Fusion offers powerful features and flexibility for designing furniture.