& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

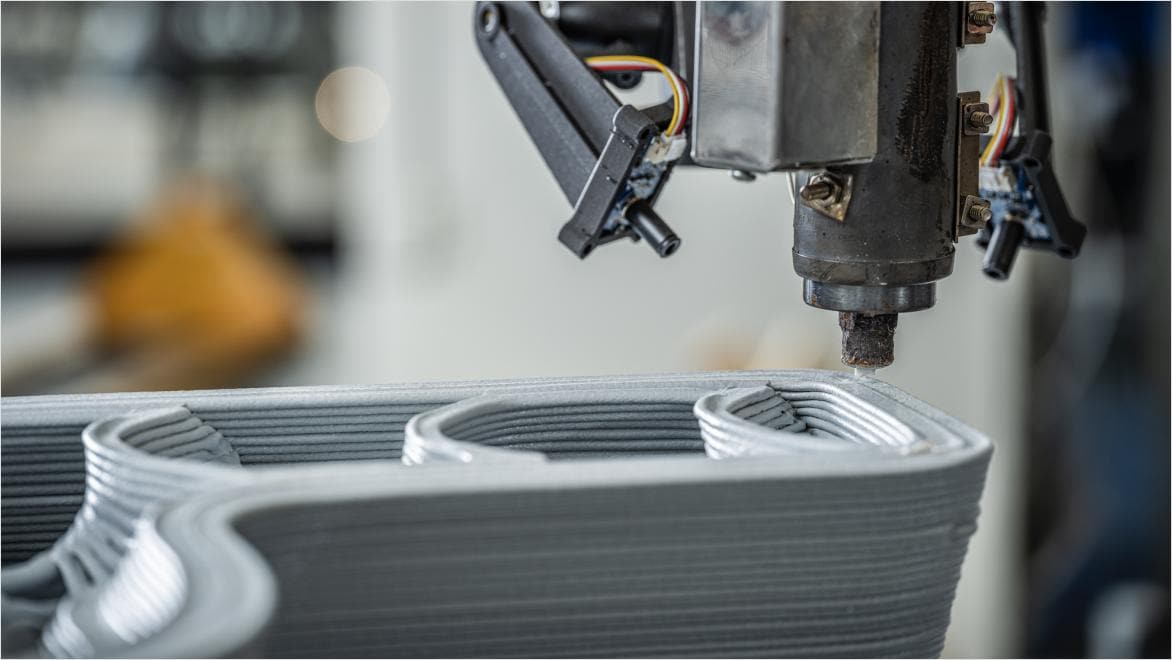

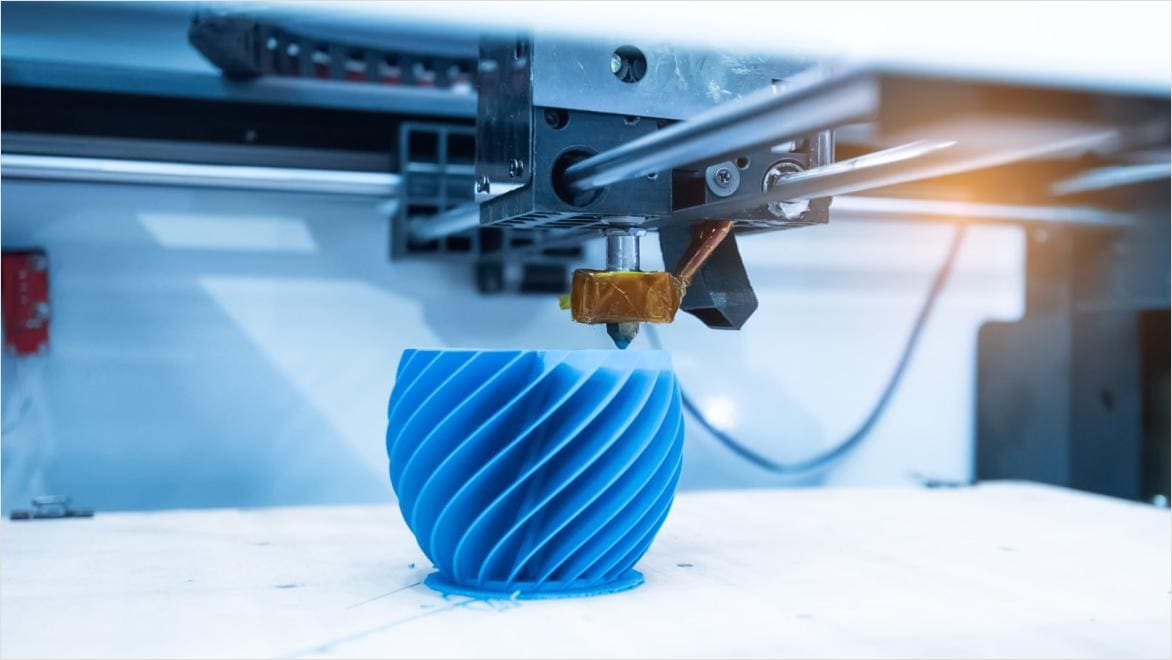

FFF (Fused filament fabrication) and FDM (Fused deposition modeling) are both 3D printing technologies that involve melting a plastic filament and extruding it through a heated nozzle to build up a 3D object layer by layer. The printer moves along the X, Y, and Z axes to accurately shape the object.

The primary difference between FFF (Fused filament fabrication) and FDM (Fused deposition modeling) is that FDM is a trademarked term used by Stratasys to refer to this process, while FFF is a more general term used across the 3D printing industry to describe the same technology.

Both technologies are similar, but FDM is a specific brand of FFF. In practice, FDM printers tend to be more commonly used in professional settings, while FFF is a more general term used in both hobbyist and professional 3D printing.

A biodegradable, easy-to-print material that offers a smooth finish. It’s great for prototyping, decorative objects, and low-stress applications.

Known for its strength and impact resistance, ABS is ideal for functional prototypes and parts that need to endure physical stress and wear.

A strong, flexible material that is resistant to impact and chemicals. PETG is great for parts requiring durability and food-safe applications.

A flexible, rubber-like material that offers great abrasion resistance. TPU is perfect for items like phone cases, seals, and gaskets.

A tough and flexible plastic, known for its durability and resistance to abrasion. Nylon is commonly used for mechanical parts like gears and bearings.

A high-strength, heat-resistant material suitable for parts exposed to high temperatures or extreme stress, used in industrial and engineering applications.

FFF 3D printing software is essential for optimizing your 3D printing process and ensuring high-quality results. FFF enables you to control key aspects of your prints, such as layer height, print speed, and material usage, while providing tools for precise design and troubleshooting.

The right FFF software can enhance print quality, reduce waste, and improve overall efficiency. Additionally, FFF software supports advanced features like simulation, part orientation, and customization, allowing you to tackle more complex projects and produce reliable, functional prototypes. Whether you're a hobbyist or a professional, using dedicated FFF software ensures better print performance and smoother workflows.

A biodegradable, easy-to-print material that offers a smooth finish. It’s great for prototyping, decorative objects, and low-stress applications.

Known for its strength and impact resistance, ABS is ideal for functional prototypes and parts that need to endure physical stress and wear.

A strong, flexible material that is resistant to impact and chemicals. PETG is great for parts requiring durability and food-safe applications.

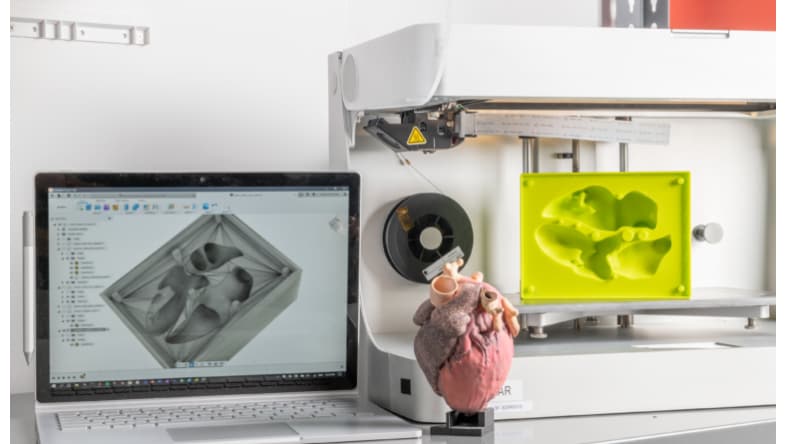

FFF enables consumer goods manufacturers to quickly prototype product designs, test functionality, and produce small batches of custom items to reduce production time.

Warping: Occurs when printed parts cool unevenly

Layer adhesion issues: Poor adhesion between layers can result in weak prints

Stringing: Fine threads of filament left on prints due to oozing of the extruder

Material inconsistency: Filament diameter or quality variations can affect prints

Print failures: Prints detaching or shifting during the process

Optimize part design and performance with unlimited cloud solves for generative design, FEA, electronic cooling, injection molding, and more.

Unlock additional capabilities for 3 to 5-axis CNC machining, sheet-based nesting and fabrication, and metals-based additive manufacturing.

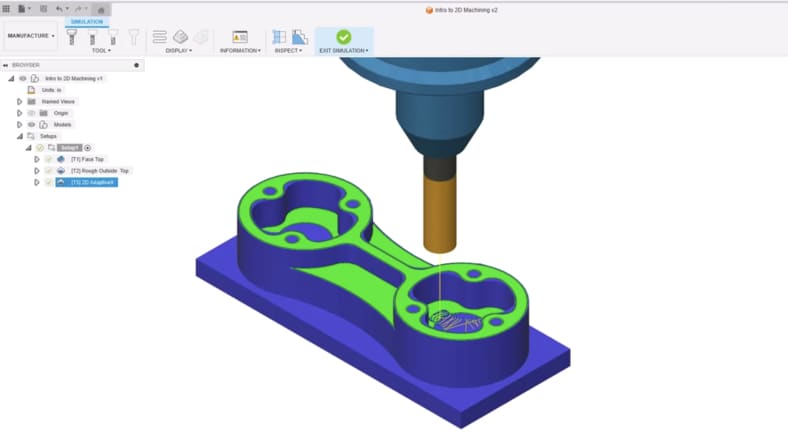

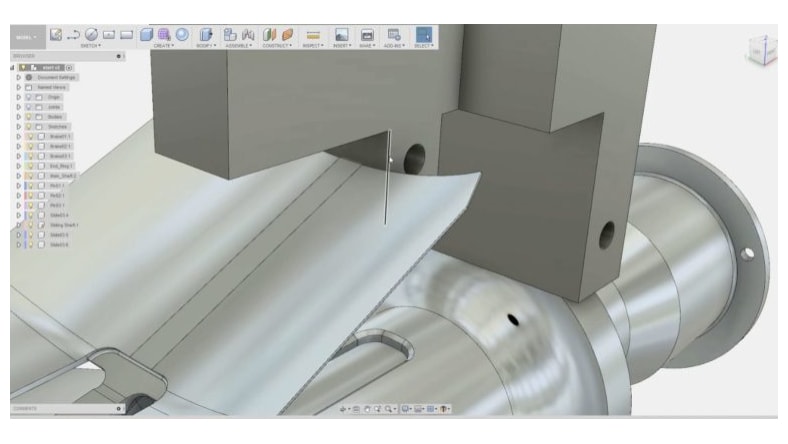

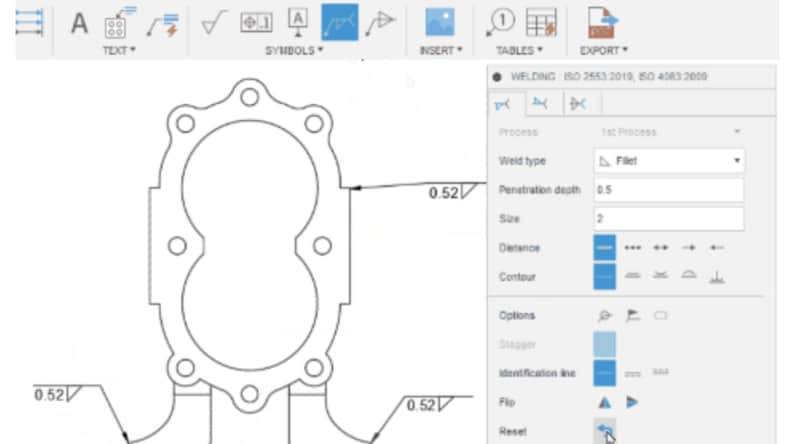

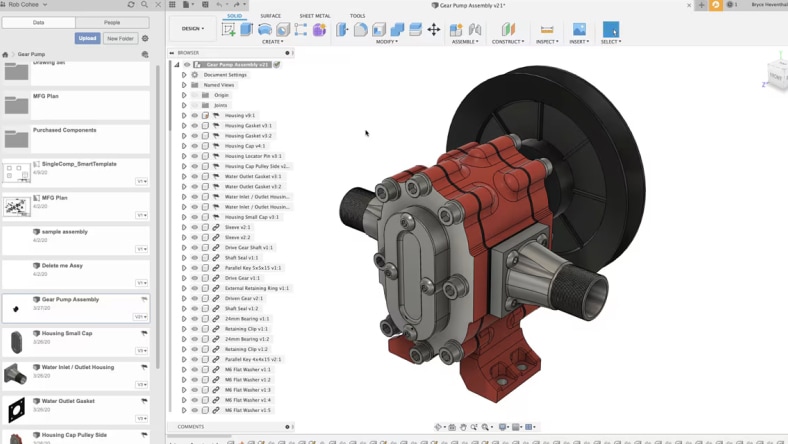

Autodesk Fusion streamlines FFF and FDM 3D printing workflows by providing an integrated platform for design, simulation, and manufacturing. Fusion enables users to create precise 3D models, optimize print settings, and simulate print outcomes before actual production.

Fusion’s tools help refine designs for better printability, reduce material waste, and ensure part durability. Seamlessly export optimized files to 3D printers to ensure a smooth transition from design to prototype with enhanced efficiency and accuracy.

Simulates toolpaths before actual printing to detect potential issues, ensuring smoother production and optimized results.

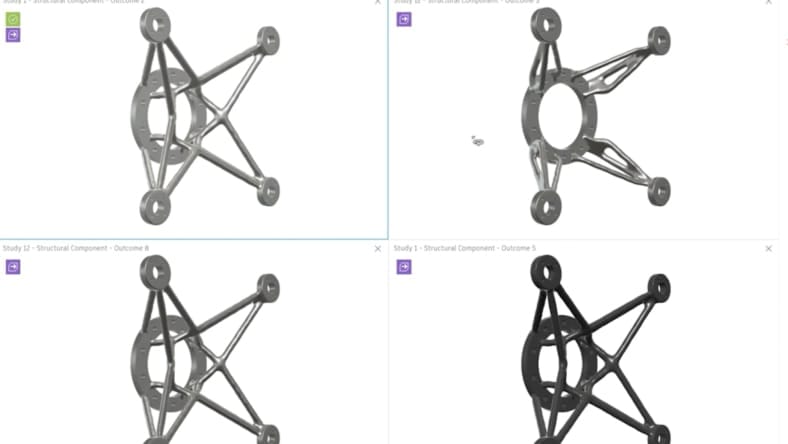

Generates multiple design alternatives based on defined constraints, optimizing for material use, weight, and performance, ensuring more efficient prints.

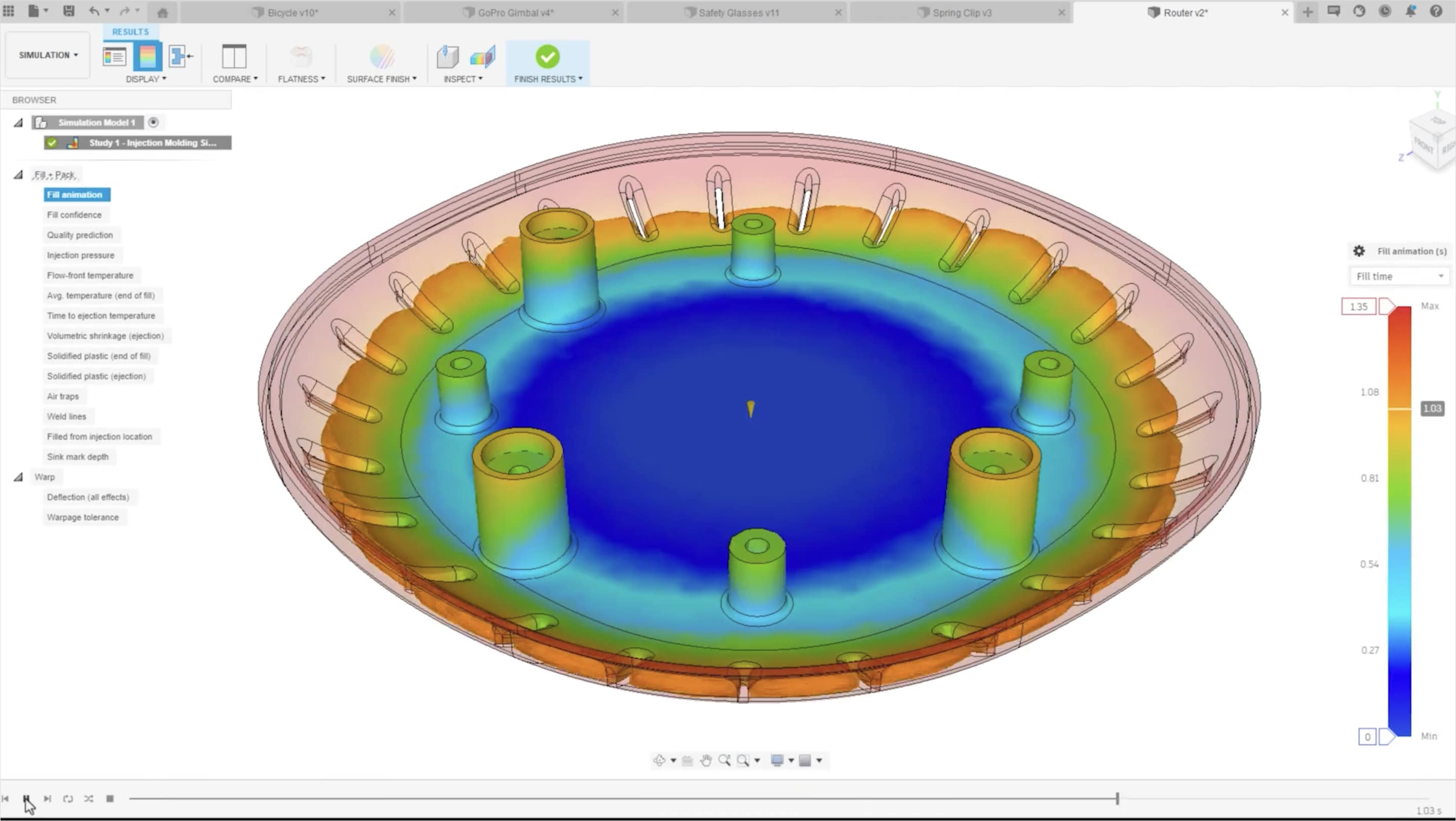

Provides stress, thermal, and deformation analysis to validate your designs for manufacturability and performance before printing.

Enables quick, flexible modifications to design geometry without requiring a history-based approach, making it easier to adapt designs for 3D printing needs.

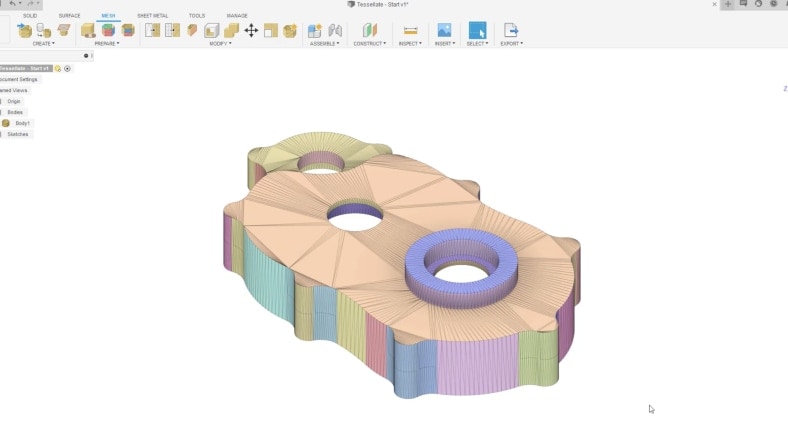

Helps prepare and edit mesh models for 3D printing by repairing errors and optimizing the geometry for better print quality.

Allows for precise control over design dimensions and features, making it easier to modify and optimize designs for 3D printing.

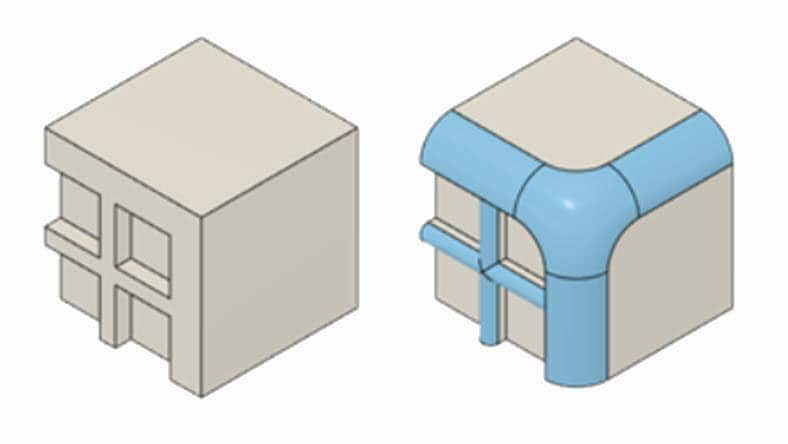

Ensures proper clearances and fit for parts, avoiding issues such as incorrect part assembly or interference in the final print.

Prepares designs for manufacturing, including settings for toolpaths, useful for hybrid workflows involving both 3D printing and traditional machining.

Streamline the design process for FFF and FDM 3D printing with Fusion’s all-in-one CAD, CAM, and CAE tools.

Comprehensive design and modeling tools

Validate and optimize print designs

Prepare designs for manufacturing

Learn how to print a singular body with variable print settings, materials, or colors, for FFF 3D printing with Fusion.

Explore how to prepare FFF 3D prints in Fusion with advanced support placement and slicing tools.

Discover Fusion's Solid Volume and Bar supports for precise, customizable FFF 3D print preparation.

Explore FFF in Fusion, featuring advanced workflows like customizable support structures, per-body settings, and multi-material printing.

Learn how to manually calibrate an FFF 3D printer's print bed using Autodesk Fusion's "Printer Bed Calibration" project for precise, tailored results.

Check out this comprehensive guide to 3D printing and 3D modeling basics, including important terminology you should know.

Optimize FFF 3D printing sustainability with better material choices, lifecycle considerations, and reduced power consumption using Fusion.

Learn more about FFF/FDM 3D printing with these top questions frequently asked by users.

FFF (Fused filament fabrication) and FDM (Fused deposition modeling) are terms used to describe the same 3D printing technology. The difference lies in the terminology: FDM is a trademarked term by Stratasys, while FFF is a more general term used to describe the same process. Both technologies work by melting a filament of material, typically plastic, and depositing it layer by layer to build up a 3D object.

FFF/FDM 3D printing works by melting a plastic filament and extruding it through a heated nozzle onto a build platform. The printer follows a digital 3D model, laying down the material layer by layer. Each layer cools and solidifies before the next one is added, building the object from the bottom up. This process allows for the creation of complex shapes and structures that would be difficult to achieve with traditional manufacturing methods. The technology is often used for prototyping, producing functional parts, and creating custom designs.

FFF/FDM 3D printing offers several benefits that make it a popular choice for a wide range of applications:

Autodesk Fusion can significantly enhance the FFF/FDM 3D printing process by providing powerful design and simulation tools:

Yes, Autodesk Fusion can help prepare models for FFF/FDM 3D printing by offering a range of tools that optimize designs for the printing process. With Fusion, you can check the printability of your design, ensuring that it meets the necessary specifications for 3D printing. The software allows you to adjust parameters like wall thickness, material usage, and support structures to ensure that the model is not only printable but also functional. Fusion’s advanced design capabilities also allow for the detection and correction of potential issues such as overhangs or areas that might require additional support. Once the model is finalized, Fusion enables easy export to formats like STL or OBJ, which are compatible with most 3D printers. By using these tools, you can streamline the preparation process and reduce the likelihood of print failures.

When using Autodesk Fusion for FFF/FDM 3D printing, several key design considerations should be taken into account to ensure the print’s success and functionality:

The Autodesk Fusion Manufacturing Extension plays a key role in supporting FFF/FDM 3D printing by optimizing models for production. It enables users to evaluate and improve the manufacturability of their designs by factoring in aspects such as material usage, part orientation, and the need for support structures. These considerations are critical to ensuring that parts are both efficient to print and cost-effective. The extension offers tools that allow users to refine their designs for FFF/FDM printing, minimizing material waste and optimizing the structure for faster and more reliable prints.

Fusion Manufacturing Extension also provides valuable insights into how parts will perform during the printing process. It helps identify potential issues like warping, material shrinkage, or insufficient strength that may arise during printing. With the extension’s capabilities, users can simulate and adjust these aspects before actual production, reducing the likelihood of print failures. By offering these advanced simulation and optimization tools, the Fusion Manufacturing Extension makes it easier for users to transition from design to finished part, ensuring that their 3D prints are not only manufacturable but also high-quality and functional.

The Autodesk Fusion Simulation Extension significantly enhances FFF/FDM 3D printing by allowing users to test the performance of their designs before physically printing them. By using advanced simulation tools, users can analyze how a part will react under various conditions, such as stress, thermal changes, or impact forces, ensuring that the part will meet performance requirements. This is especially useful in FFF/FDM printing, where layer adhesion and material properties play a crucial role in the final part's strength and durability. The ability to simulate these factors helps designers identify weaknesses or potential failure points in the design, which can be corrected before printing, saving both time and material costs.

Fusion Simulation Extension also helps optimize designs specifically for FFF/FDM printing by predicting issues such as warping, shrinkage, or part deformation during the printing process. It provides insights into how different materials and printing orientations affect part performance, allowing for informed decisions about the best design strategies. By leveraging this extension, designers can ensure that their 3D printed parts are not only functional but also reliable, reducing the need for costly prototyping and multiple print iterations. This enhanced simulation capability makes Autodesk Fusion a powerful tool for improving the quality and efficiency of FFF/FDM 3D printing.