& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

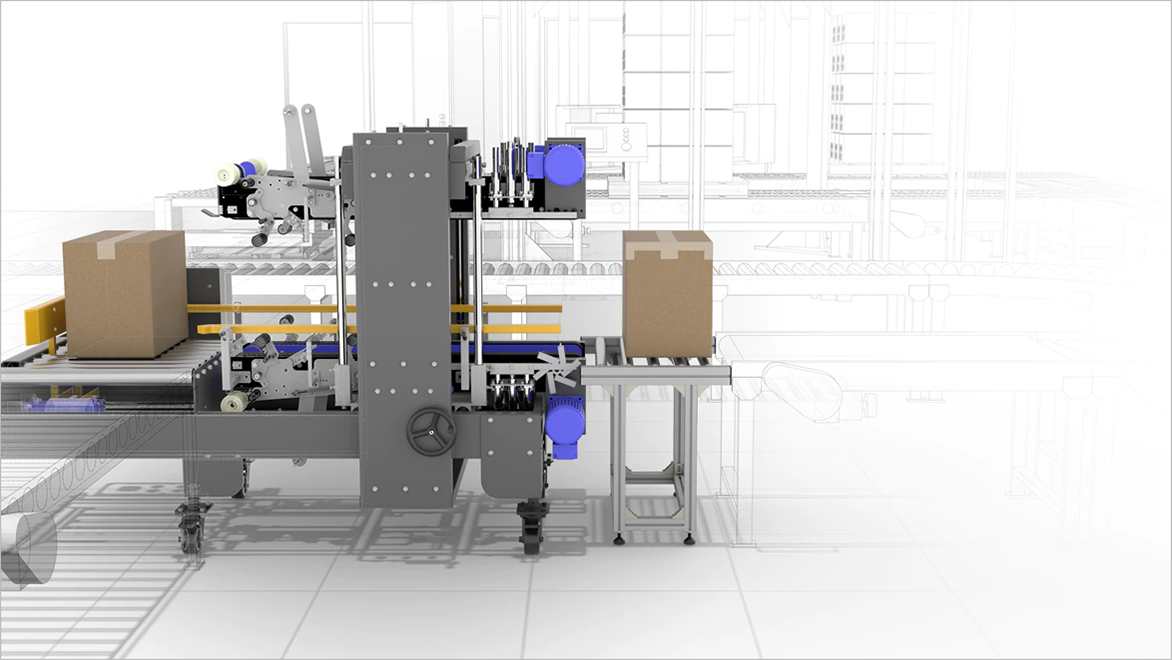

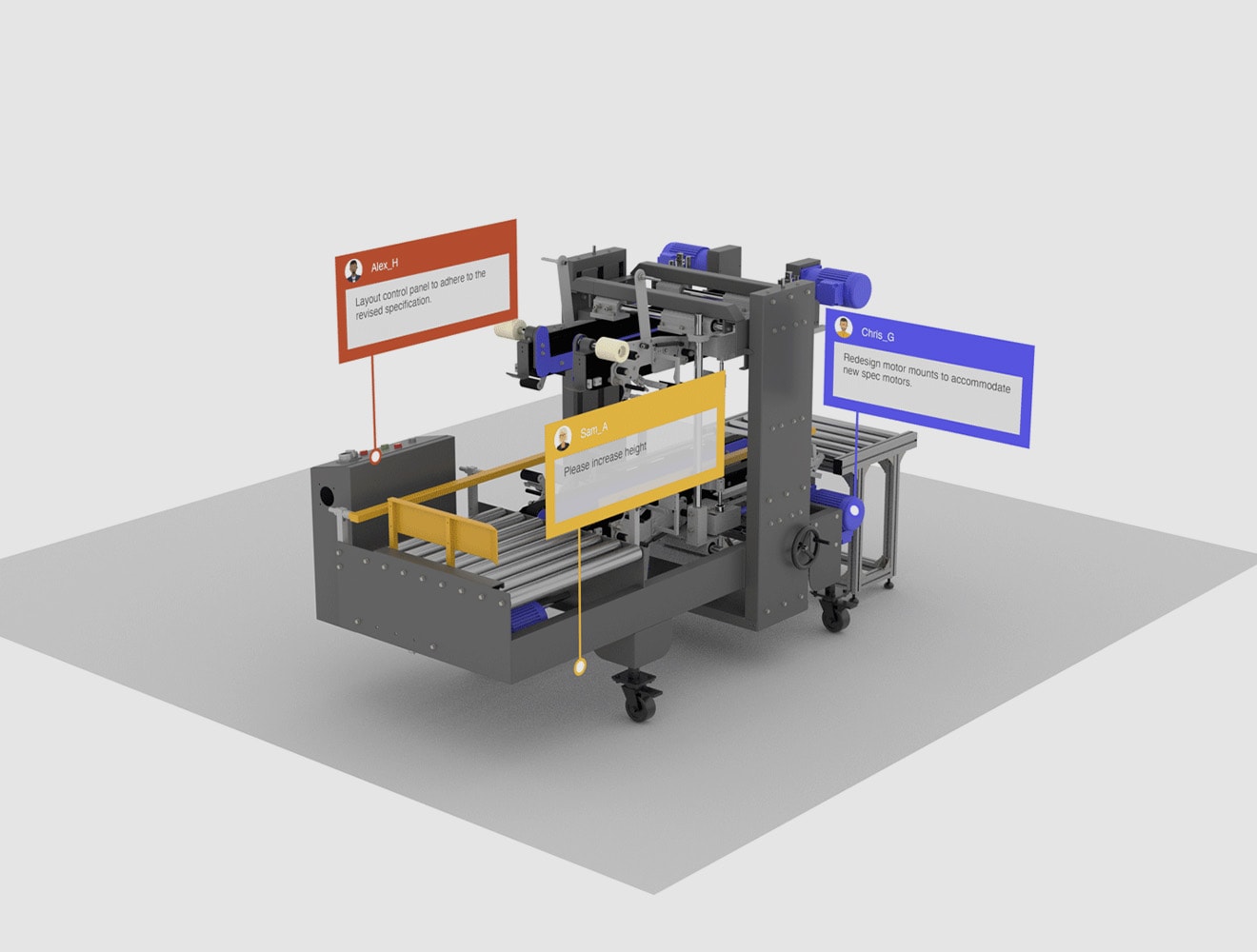

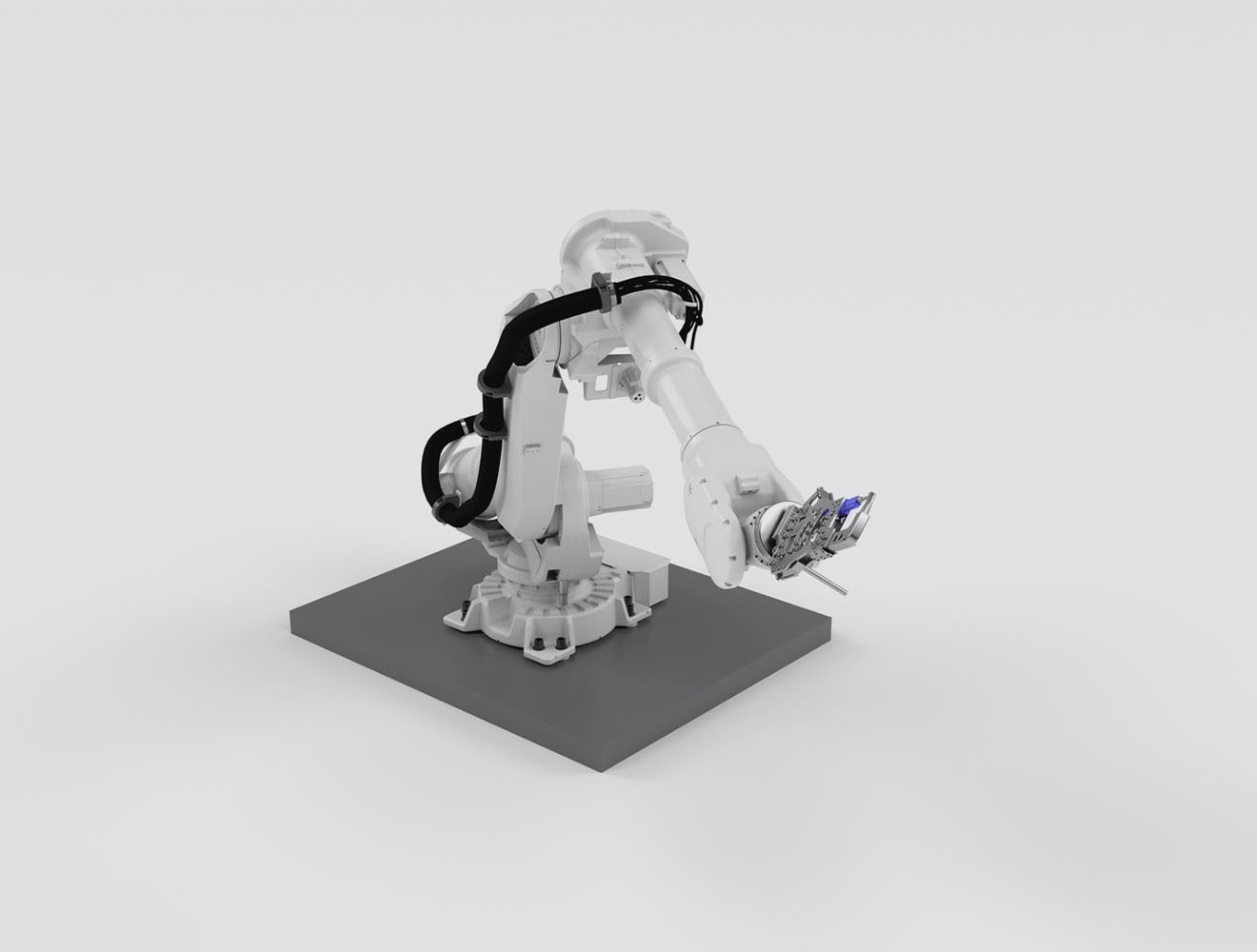

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

- Choose your plan

- Buying with Autodesk

- Special offers

- Purchase by phone+44 203 318 4259

- Help with buying