Product Designers and Engineers:

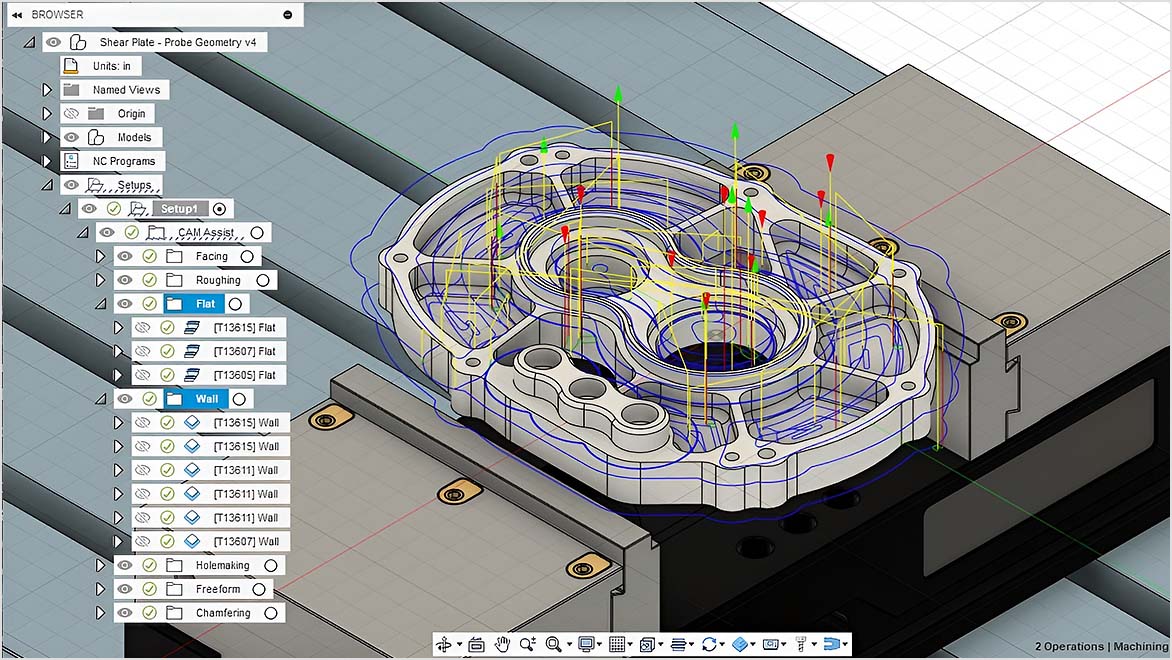

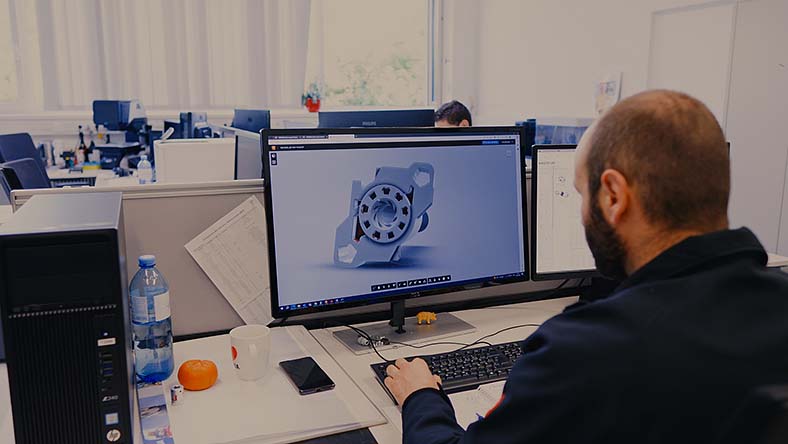

- Mechanical Engineers: Use Fusion for designing mechanical components, validating designs through simulation, and preparing them for manufacturing.

- Industrial Designers: Create aesthetically pleasing and functional product designs, leveraging generative design and advanced modeling tools.

- Electrical Engineers: Integrate mechanical and electronic design by using ECAD/MCAD workflows.

Manufacturing Professionals:

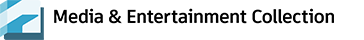

- CNC Machinists: Program complex toolpaths for CNC machining operations such as milling, turning, and cutting.

- Toolmakers: Design and manufacture custom tools, dies, molds, and fixtures required for manufacturing processes.

- Fabricators and Machinists: Use the platform for preparing parts for laser cutting, waterjet cutting, and other fabrication processes.

Additive Manufacturing Specialists:

- Utilise Fusion for 3D printing, including designing, optimising, and preparing parts for various additive manufacturing technologies.

Small and Medium-sized Enterprises (SMEs):

- Fusion is particularly popular among smaller companies due to its cost-effectiveness and all-in-one functionality, making it accessible for businesses without large budgets for multiple specialised software packages.

Educational Institutions and Students:

- Widely used in academic settings to teach students CAD/CAM/CAE principles and hands-on design and manufacturing skills, preparing them for careers in engineering and manufacturing.

Entrepreneurs and Startups:

- Ideal for startups and entrepreneurs involved in product development due to its affordability, cloud-based collaboration, and rapid prototyping capabilities.

Industries:

- Automotive: Used for designing components, tooling, and fixtures for automotive manufacturing.

- Aerospace: Utilised for designing high-precision parts and performing simulations to meet stringent industry standards.

- Consumer Goods: Helps in developing consumer products from concept to production, including prototyping and testing.

- Medical Devices: Supports the design and manufacture of medical devices, prosthetics, and tools, ensuring compliance with industry regulations.

- Industrial Equipment: Facilitates the design and production of complex machinery and equipment.

Overall, Fusion for Manufacturing caters to a broad spectrum of users who need a unified platform to bridge the gap between design and manufacturing.