& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

Professional CAD/CAM tools built on Inventor and AutoCAD

Any referenced datasets can be downloaded from "Module downloads" in the module overview.

Transcript

00:03

The deterioration of pipes in a water distribution system is a major challenge for water utilities.

00:10

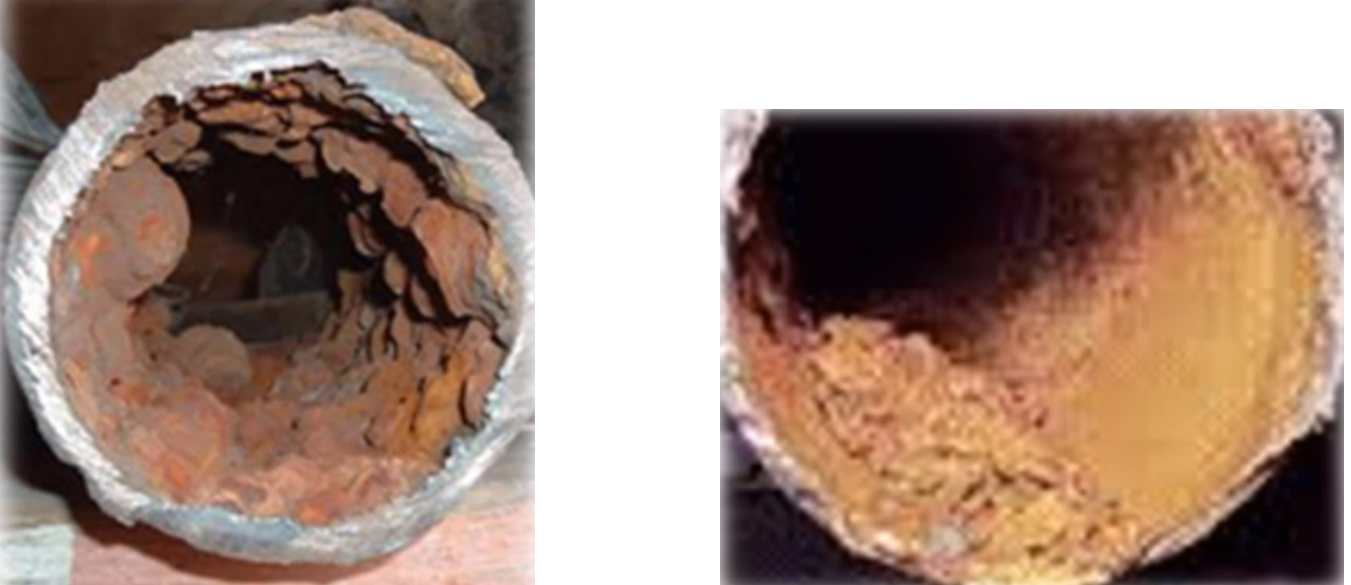

In some pipes, depending on their material and age, deposits can form on the inside walls.

00:17

This can cause hydraulic capacity to decrease over time.

00:22

Deposits can result from chemical precipitation, microbiological activity, and in the case of cast iron pipes, corrosion buildup.

00:30

Within a water distribution system, unidirectional flushing (UDF) can help to improve water quality.

00:37

Deposits can increase pipe roughness and decrease effective pipe diameter, possibly resulting in:

00:44

Inability to deliver fire flows.

00:46

Increased disinfectant demand.

00:49

Chlorine degradation.

00:52

Complaints about water taste, odor, and color.

00:56

And potentially, public health issues.

00:59

Furthermore, reduced effective pipe diameter can lead to reduced hydraulic capacity,

01:05

increased pumping costs, and lower residual pressure.

01:09

Certain pipe materials, such as cast iron, are more susceptible to these types of issues.

01:16

Unidirectional flushing can prolong the life expectancy of a distribution system and reduce the potential for waterborne diseases.

01:24

It can help remove biofilm growth and particulates that lead to chlorine loss, as well as taste, odor, and color concerns.

01:33

In InfoWater Pro UDF, unidirectional flushing is performed by first isolating a portion of the distribution system,

01:41

then opening fire hydrants or flushing valves.

01:44

These actions can ideally create enough velocity to scour pipes and remove unwanted materials.

01:50

The flushed water is then discharged through a hydrant.

01:54

Generally, unidirectional flushing begins in portions of the system closest to the water sources,

02:00

proceeding to the outward extents of the system.

02:03

It is important to understand the distinction among the three general flushing methods:

02:08

UDF, conventional flushing, and continuous blow-off.

02:13

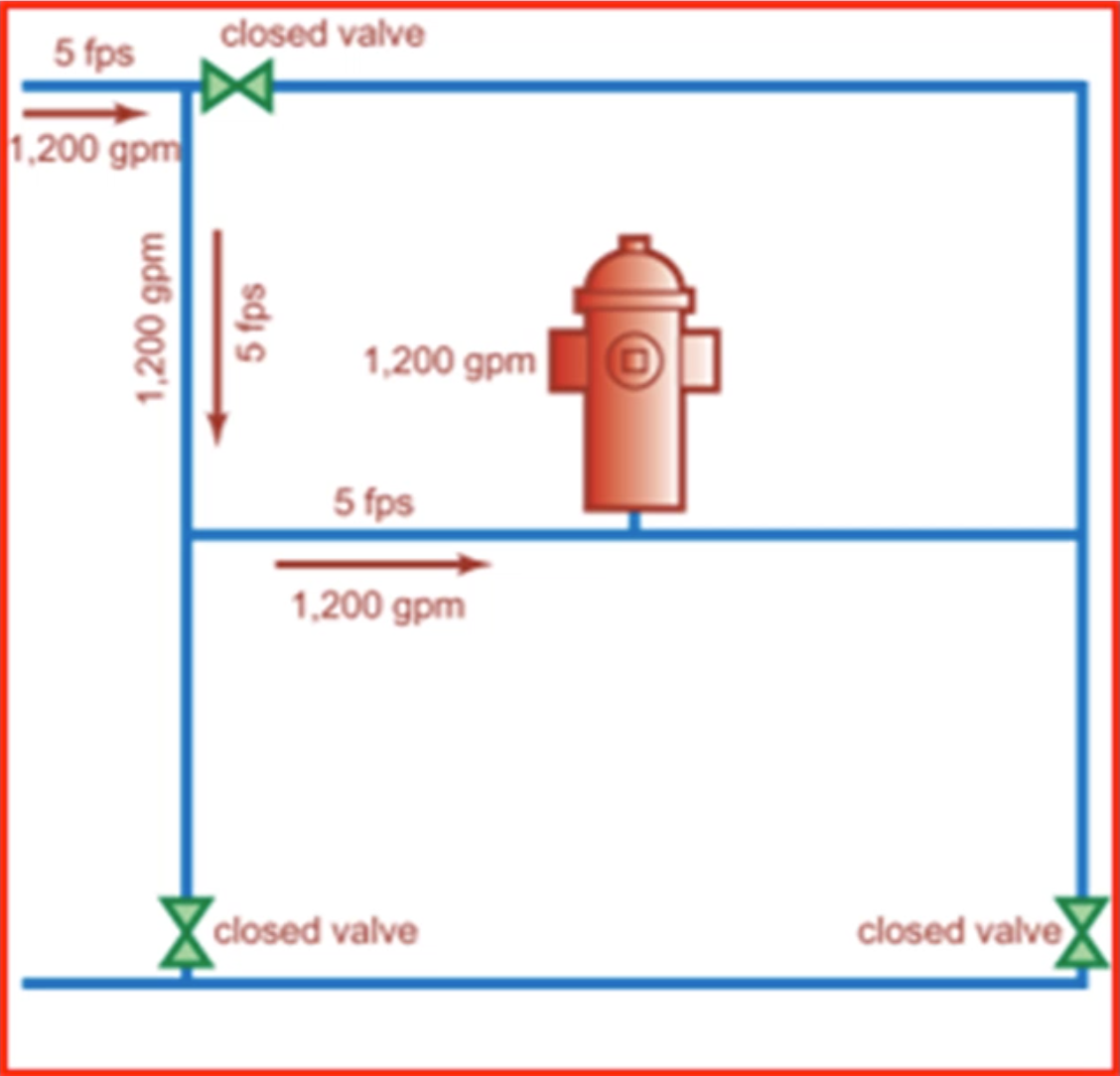

UDF involves a systematic plan to direct flushed water in a single direction along the pipe to maximize velocity.

02:21

To do this, you close valves and open hydrants to create a one-way flow in the water mains.

02:27

This linear flow results in higher velocities,

02:31

typically 5 or 6 feet per second.

02:33

This method maximizes linear velocity near the pipe wall, making it ideal for removing biofilm and other more hardened corrosion materials.

02:42

The flush begins at a clean water source and ends at a hydrant, so that only clean water is used.

02:49

UDF also eliminates the chances of dirty water and debris being inadvertently transported

02:55

around the system and is the most efficient flushing method.

02:59

UDF is not a feasible solution in emergency situations, as it takes proper planning and time to carry out.

03:07

Conventional flushing is done without control of the flow direction—for example,

03:13

opening several hydrants in the same area at once until the water clears up.

03:17

This method is effective for removing loose sediment, but less effective at raising pipeline velocities.

03:25

Conventional flushing yields velocities of less than 2 feet per second, so it is not effective at removing deposits or biofilm.

03:33

It can also cause dirty water and debris to be inadvertently transported around the system.

03:39

As it is less effective at raising velocities, this method often requires larger amounts of water, decreasing its efficiency.

03:47

Conventional flushing is often used reactively to fix areas of poor water quality, or in response to aesthetic complaints.

03:56

Continuous blow-off consists of a small, continuous or intermittent water usage to refresh the line.

04:03

This is usually seen as a short-term preventive strategy and is often used to solve stagnation problems.

04:10

It has a comparatively low velocity of less than 1 foot per second, and can use a large amount of water, resulting in poor efficiency.

Video transcript

00:03

The deterioration of pipes in a water distribution system is a major challenge for water utilities.

00:10

In some pipes, depending on their material and age, deposits can form on the inside walls.

00:17

This can cause hydraulic capacity to decrease over time.

00:22

Deposits can result from chemical precipitation, microbiological activity, and in the case of cast iron pipes, corrosion buildup.

00:30

Within a water distribution system, unidirectional flushing (UDF) can help to improve water quality.

00:37

Deposits can increase pipe roughness and decrease effective pipe diameter, possibly resulting in:

00:44

Inability to deliver fire flows.

00:46

Increased disinfectant demand.

00:49

Chlorine degradation.

00:52

Complaints about water taste, odor, and color.

00:56

And potentially, public health issues.

00:59

Furthermore, reduced effective pipe diameter can lead to reduced hydraulic capacity,

01:05

increased pumping costs, and lower residual pressure.

01:09

Certain pipe materials, such as cast iron, are more susceptible to these types of issues.

01:16

Unidirectional flushing can prolong the life expectancy of a distribution system and reduce the potential for waterborne diseases.

01:24

It can help remove biofilm growth and particulates that lead to chlorine loss, as well as taste, odor, and color concerns.

01:33

In InfoWater Pro UDF, unidirectional flushing is performed by first isolating a portion of the distribution system,

01:41

then opening fire hydrants or flushing valves.

01:44

These actions can ideally create enough velocity to scour pipes and remove unwanted materials.

01:50

The flushed water is then discharged through a hydrant.

01:54

Generally, unidirectional flushing begins in portions of the system closest to the water sources,

02:00

proceeding to the outward extents of the system.

02:03

It is important to understand the distinction among the three general flushing methods:

02:08

UDF, conventional flushing, and continuous blow-off.

02:13

UDF involves a systematic plan to direct flushed water in a single direction along the pipe to maximize velocity.

02:21

To do this, you close valves and open hydrants to create a one-way flow in the water mains.

02:27

This linear flow results in higher velocities,

02:31

typically 5 or 6 feet per second.

02:33

This method maximizes linear velocity near the pipe wall, making it ideal for removing biofilm and other more hardened corrosion materials.

02:42

The flush begins at a clean water source and ends at a hydrant, so that only clean water is used.

02:49

UDF also eliminates the chances of dirty water and debris being inadvertently transported

02:55

around the system and is the most efficient flushing method.

02:59

UDF is not a feasible solution in emergency situations, as it takes proper planning and time to carry out.

03:07

Conventional flushing is done without control of the flow direction—for example,

03:13

opening several hydrants in the same area at once until the water clears up.

03:17

This method is effective for removing loose sediment, but less effective at raising pipeline velocities.

03:25

Conventional flushing yields velocities of less than 2 feet per second, so it is not effective at removing deposits or biofilm.

03:33

It can also cause dirty water and debris to be inadvertently transported around the system.

03:39

As it is less effective at raising velocities, this method often requires larger amounts of water, decreasing its efficiency.

03:47

Conventional flushing is often used reactively to fix areas of poor water quality, or in response to aesthetic complaints.

03:56

Continuous blow-off consists of a small, continuous or intermittent water usage to refresh the line.

04:03

This is usually seen as a short-term preventive strategy and is often used to solve stagnation problems.

04:10

It has a comparatively low velocity of less than 1 foot per second, and can use a large amount of water, resulting in poor efficiency.

The deterioration of pipes in a water distribution system is a major challenge for water utilities. Unidirectional flushing (UDF) can help to improve water quality.

How to buy

Privacy | Do not sell or share my personal information | Cookie preferences | Report noncompliance | Terms of use | Legal | © 2025 Autodesk Inc. All rights reserved

Sign in to start learning

Sign in for unlimited free access to all learning content.Save your progress

Take assessments

Receive personalized recommendations

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.