CAD software systems are diverse, catering to design and engineering requirements with varying levels of control and functionality. Freeform modellers such as ZBrush and Autodesk Mudbox represent one end of the spectrum, offering minimal dimensional control for users to sculpt designs, akin to virtual clay. In contrast, parametric modellers such as CATIA, Creo and OnShape provide exhaustive control, so every design aspect be meticulously defined by dimensions and constraints. This approach builds a comprehensive history of the model’s development, enabling deep customisation scripting.

Between these extremes lie other modelling techniques including polygonal (mesh) modelling, utilised by Blender and Autodesk 3ds Max; solid modelling, found in SolidWorks and SolidEdge; and surface modelling, as seen in software such as Autodesk Alias and Rhinoceros. Each method offers distinct advantages, from simple shape manipulation to creating complex, ready-for-manufacture models.

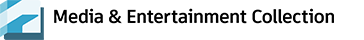

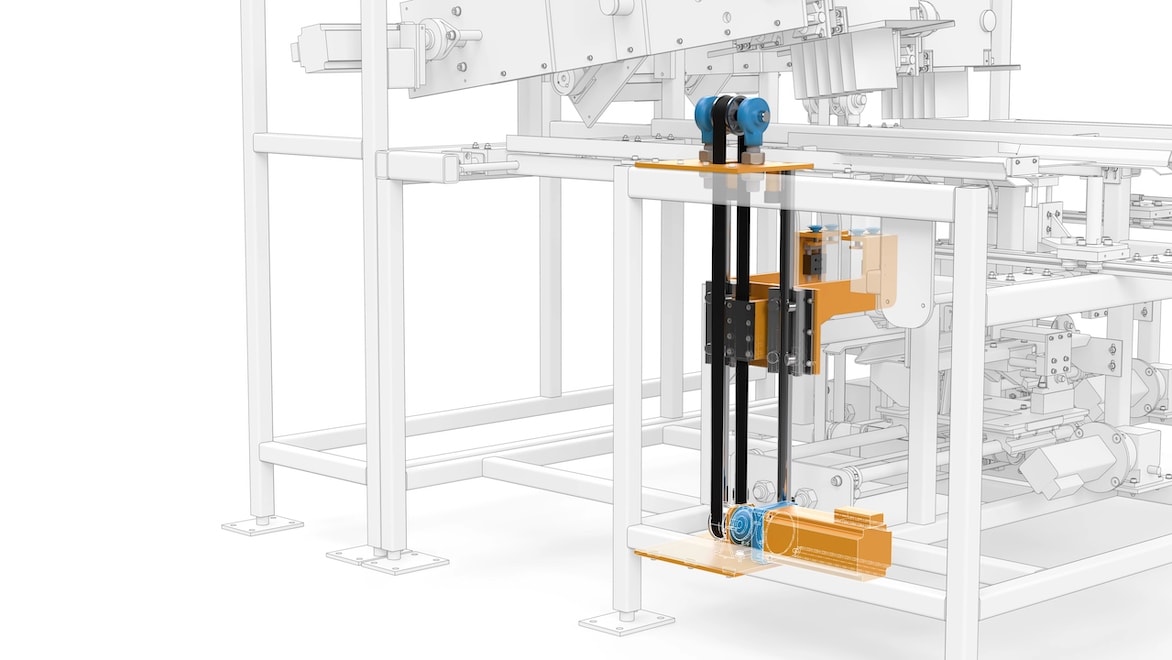

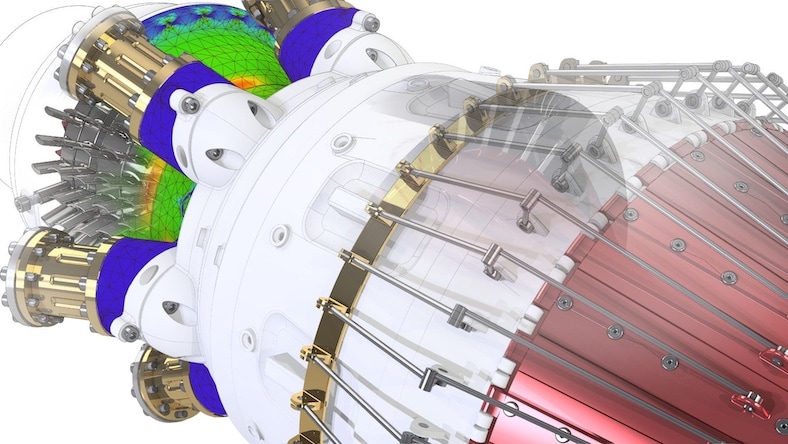

In the realm of 3D CAD software, Autodesk embraces a hybrid approach across a suite of design products, blending the strengths of various modelling techniques to serve a broad spectrum of industry needs. Autodesk’s software–including Autodesk AutoCAD, Autodesk Fusion and Autodesk Inventor–integrates features of solid and surface modelling with parametric capabilities for a highly flexible design process that accommodates everything from initial concept sketches to final manufacturing-ready models. Fusion combines mesh and solid modelling, seamlessly transitioning between design phases. AutoCAD’s extensive toolset accommodates a wide range of design tasks, making it a versatile choice for professionals across disciplines. Inventor provides specialised toolsets that automate the 3D modelling of sheet metal, weld frame, piping and electrical components. It also features powerful rules-based technology, so designers quickly create new configurations of existing designs for the next project or to satisfy customer requests.